We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-23 Origin: Site

Cooling tower scaling is one of those industrial problems that rarely announces itself—but when it does, the damage is already done. At first, your cooling system seems to operate normally. Temperatures stay within range, production runs smoothly, and energy consumption appears stable. Yet inside the system, dissolved minerals are quietly settling onto heat transfer surfaces, slowly forming hard, insulating deposits.

Over time, this buildup—known as cooling tower scaling—reduces efficiency, increases operating costs, and shortens equipment lifespan. For industrial facilities, understanding the main causes of cooling tower scaling is the key to preventing unplanned downtime and expensive repairs.

In industrial cooling systems, water is constantly evaporated to remove heat. While evaporation is essential, it also concentrates dissolved minerals in the circulating water. When conditions are right, these minerals leave the water and solidify on surfaces.

Scaling is not a rare event. In fact, it is one of the most common operational challenges faced by cooling towers in power plants, chemical facilities, manufacturing plants, and HVAC systems.

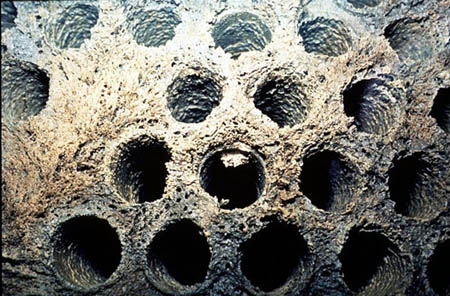

Cooling tower scaling refers to the formation of hard, crystalline mineral deposits on internal surfaces such as heat exchangers, piping, fill media, and basins. These deposits typically consist of calcium carbonate, magnesium compounds, and other inorganic salts.

Think of it like limescale in a household kettle—except magnified across hundreds of square meters of industrial equipment.

Although often mentioned together, scaling is different from other water-related issues:

Scaling is mineral-based and hard

Fouling is caused by biological growth or debris

Corrosion is chemical deterioration of metal surfaces

Scaling is particularly dangerous because once it hardens, removal becomes difficult and costly.

Even a thin layer of scale acts as thermal insulation. This reduces heat transfer efficiency and forces the system to work harder to achieve the same cooling effect. As a result:

Energy consumption increases

Operating temperatures rise

Equipment stress accelerates

Maintenance frequency grows

Ignoring scaling doesn’t just hurt performance—it quietly drains budgets.

Water quality is the foundation of scaling behavior. Industrial cooling towers often rely on local make-up water sources that contain varying mineral concentrations.

Hard water contains high levels of calcium and magnesium ions. As water evaporates inside the cooling tower, these minerals become more concentrated until they exceed their solubility limit and precipitate onto surfaces.

Among all scale types, calcium carbonate is the most common and most problematic. It forms rapidly, bonds tightly, and resists mechanical removal.

Cycles of concentration describe how many times minerals are concentrated in recirculating water compared to make-up water. Higher cycles conserve water—but they also push minerals closer to precipitation.

Insufficient blowdown allows mineral levels to rise unchecked. Too much blowdown wastes water and chemicals. Finding the optimal balance is essential for scale control.

Heat accelerates scale formation. The hotter the surface, the lower the solubility of many minerals.

Heat exchanger tubes, condenser surfaces, and high-load fill areas become prime locations for scale buildup because elevated temperatures encourage mineral precipitation.

Water chemistry is not a “set it and forget it” process. Small imbalances can have large consequences.

High pH levels dramatically increase the likelihood of calcium carbonate scaling. Even slight deviations can trigger rapid deposition.

Excess alkalinity and rising conductivity act like fuel for scale formation, especially under high evaporation conditions.

A poorly designed or poorly maintained water treatment program is one of the fastest ways to invite scaling.

Scale inhibitors disrupt crystal growth before deposits harden. Without proper inhibitor selection and dosing, scaling becomes unavoidable.

Where water slows down, minerals settle. Dead zones are silent troublemakers.

Uneven water distribution, stagnant basins, and oversized piping sections create ideal conditions for localized scaling.

Cooling tower design plays a critical role in scaling behavior.

Rough surfaces, low-quality materials, and inefficient water distribution systems provide anchor points where scale can easily form and spread.

Environmental factors also influence scaling risk.

Seasonal shifts in temperature and water chemistry can suddenly increase scaling potential if treatment programs are not adjusted accordingly.

In one industrial manufacturing facility, undetected scaling reduced heat exchanger efficiency by over 30%. Energy consumption rose steadily, and emergency shutdowns became frequent. After upgrading the cooling tower system and optimizing water treatment, efficiency was restored within months—saving significant operational costs.

Early detection makes all the difference. Common warning signs include:

Rising approach temperatures

Increased fan or pump energy usage

Visible white or gray deposits

Frequent cleaning requirements

Spotting these indicators early can prevent major failures.

Scaling increases mechanical stress on pumps, fans, and heat exchangers. Over time, it accelerates wear, shortens service life, and raises replacement costs—turning a manageable issue into a capital expense.

The best strategy against scaling is prevention. This includes:

Proper water chemistry control

Reliable water treatment programs

High-quality cooling tower design

Continuous monitoring and adjustment

A well-designed cooling tower improves water distribution, minimizes dead zones, and reduces scaling risk from the start.

Manufacturers like Mach Cooling (https://www.machcooling.com/) focus on optimized hydraulic design, durable materials, and efficient heat transfer performance. Their cooling towers are engineered to reduce stagnant areas, improve water flow, and support effective water treatment—helping industrial systems stay efficient while minimizing long-term scaling risks.

Cooling tower scaling doesn’t happen overnight. It’s the result of water quality, temperature, chemistry, design, and operating conditions working together against your system. By understanding the main causes of cooling tower scaling and partnering with experienced manufacturers like Mach Cooling, industrial facilities can protect equipment, reduce energy costs, and maintain reliable cooling performance for years to come.