We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-05 Origin: Site

Choosing the right industrial cooling tower for your plant is not just a technical decision—it’s a strategic one. A well-selected cooling tower improves production efficiency, reduces energy and water consumption, and extends the lifespan of your equipment. On the other hand, the wrong choice can lead to frequent downtime, excessive operating costs, and long-term reliability issues.

So how do you make the right call? Let’s walk through the process step by step, in plain English.

An industrial cooling tower acts like a heat-release valve for your entire system. It removes unwanted heat from process water and releases it into the atmosphere, keeping critical equipment running within safe temperature limits.

From power plants and chemical facilities to steel mills and large HVAC systems, industrial cooling towers are essential wherever heat rejection is required.

Selecting a cooling tower isn’t about buying the biggest or the cheapest option. It’s about balance.

A properly matched industrial cooling tower helps you:

Maintain stable process temperatures

Reduce electricity and water consumption

Lower maintenance and chemical treatment costs

Improve system reliability and operational safety

Think of it like choosing the right engine for a vehicle—too small and it struggles, too large and it wastes fuel.

Before comparing suppliers or designs, you must clearly understand your plant’s operating conditions.

Heat load refers to the total amount of heat your system needs to reject. Cooling towers are typically sized in tons of refrigeration or kcal/hr. Accurate heat load calculations prevent both underperformance and unnecessary overspending.

Pay close attention to inlet and outlet water temperatures. The cooling range and approach temperature directly impact tower size and efficiency.

Local weather matters more than many people realize. High wet-bulb temperatures, humidity, and seasonal variations all affect cooling tower performance.

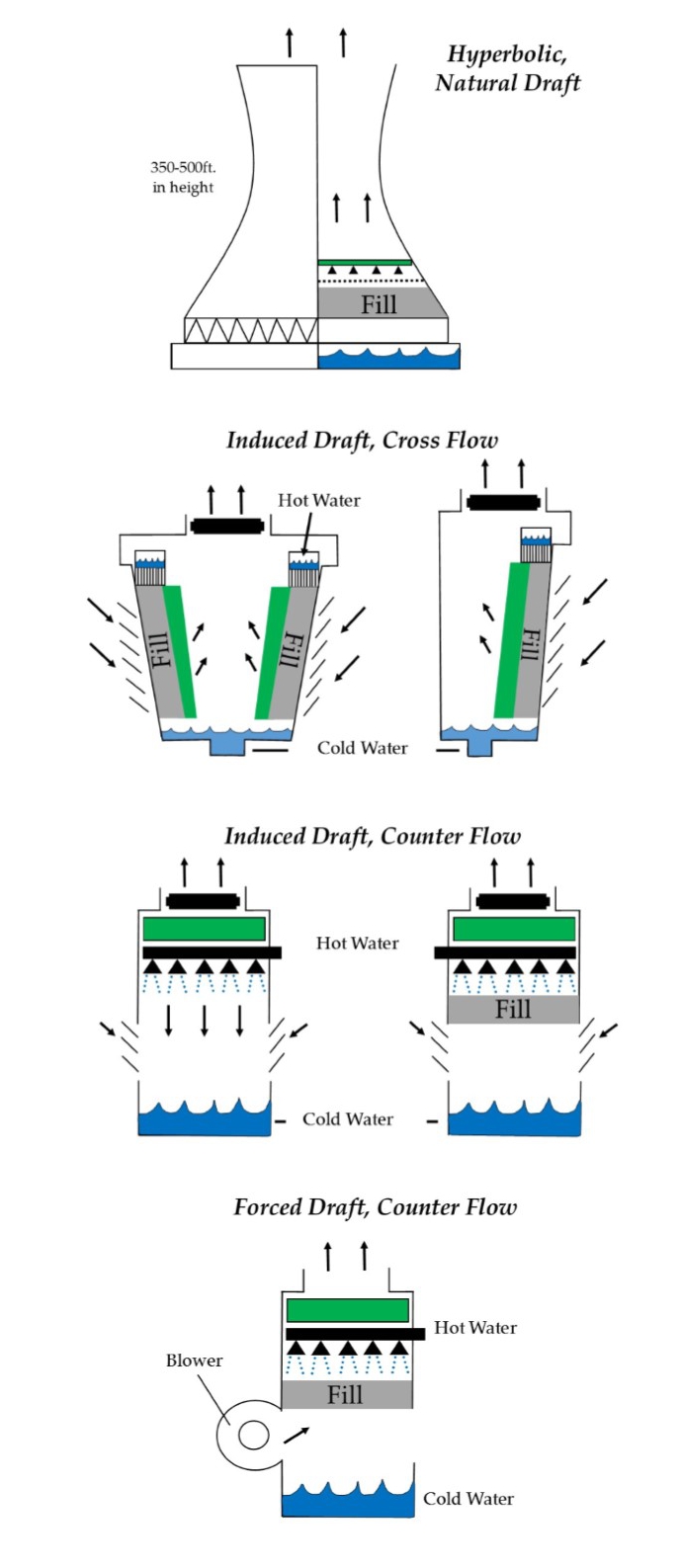

Open cooling towers allow process water to directly contact air. They are widely used due to their high efficiency and lower initial cost, but they require proper water treatment to control scaling and contamination.

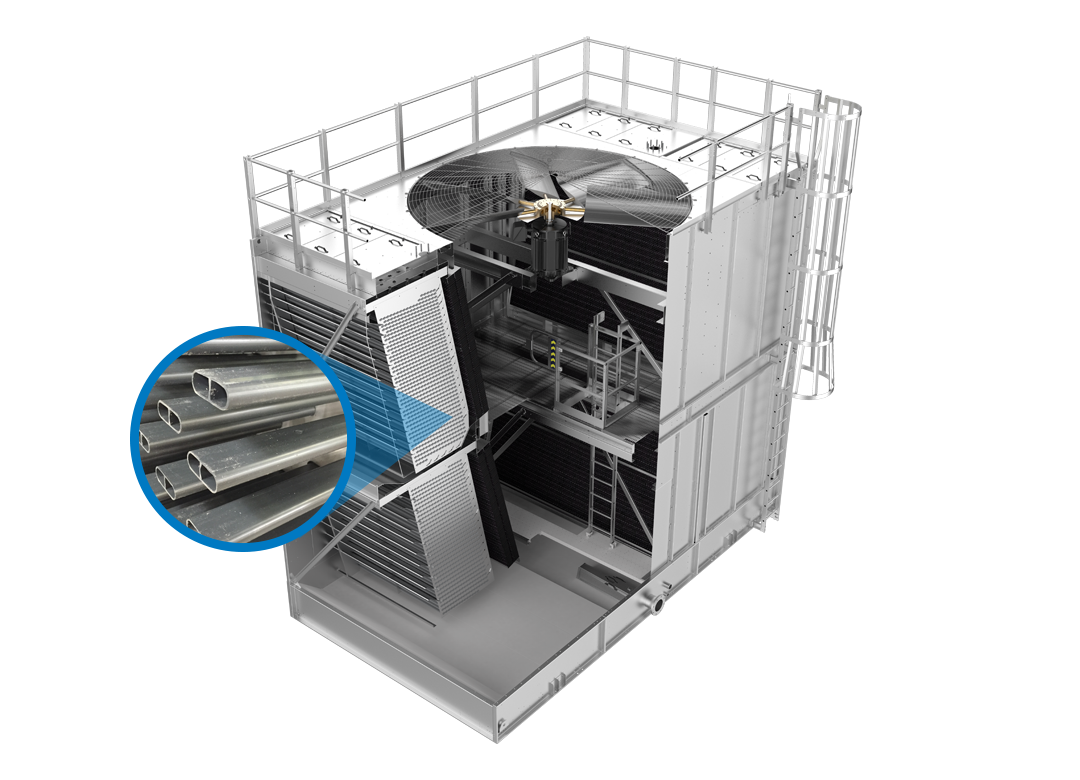

In closed circuit systems, process fluid flows inside a coil and is isolated from the atmosphere. These towers are ideal for applications requiring cleaner operation and reduced fouling.

Dry cooling towers use air only and consume minimal water, while hybrid designs combine dry and wet cooling. These solutions are increasingly popular in water-scarce regions.

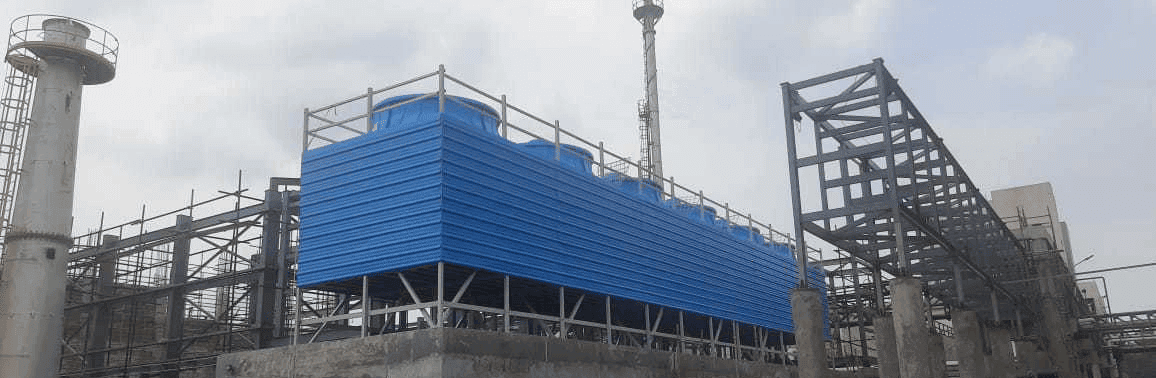

FRP (fiber-reinforced plastic) towers are lightweight, corrosion-resistant, and cost-effective. They are commonly used in chemical plants and HVAC applications.

All-steel cooling towers are built for heavy-duty industrial environments. They offer superior mechanical strength, fire resistance, and long-term durability, making them ideal for power generation and metallurgical industries.

Advanced coatings such as hot-dip galvanizing and magnesium-aluminum-zinc layers significantly extend service life in harsh environments.

![]()

High-efficiency axial fans combined with premium motors reduce power consumption. Variable frequency drives (VFDs) allow fan speed adjustment based on real-time demand.

Low-drift eliminators minimize water carryover, reducing makeup water demand and operating costs.

Water quality can make or break a cooling tower system. Poor water management leads to scaling, corrosion, and biological growth.

Key factors include:

Makeup water hardness

Blowdown control

Compatibility with chemical treatment programs

A well-designed cooling tower works hand in hand with proper water treatment.

![]()

Limited space? Modular industrial cooling towers are ideal for rooftop installations and retrofit projects. Structural load capacity, wind resistance, and seismic design should always be evaluated during planning.

Industrial cooling towers must comply with local noise and environmental regulations. Low-noise fans, acoustic enclosures, and sound attenuators help ensure quiet operation, even in urban or residential areas.

Easy access for inspection, standardized components, and durable materials simplify maintenance. With proper operation and care, a high-quality industrial cooling tower can deliver reliable service for over 20 years.

Modern cooling towers increasingly use smart monitoring systems to track temperatures, fan performance, and water quality in real time. Automation improves efficiency, reduces manual intervention, and prevents unexpected failures.

Ensure your cooling tower meets recognized standards such as CTI, ASHRAE, ISO, and relevant local regulations. Certification reflects product quality and performance reliability.

The lowest purchase price rarely means the lowest total cost. When choosing an industrial cooling tower, consider:

Energy consumption

Water usage

Maintenance frequency

Expected service life

Lifecycle cost analysis always provides a clearer picture than upfront price alone.

Mach Cooling (https://www.machcooling.com/) is a professional industrial cooling tower manufacturer offering customized solutions for global clients. With advanced production facilities, strict quality control, and extensive export experience, Mach Cooling provides:

Open and closed circuit cooling towers

All-steel and FRP industrial cooling towers

Energy-efficient and modular designs

Technical support from design to installation

Mach Cooling is not just a supplier—it’s a long-term partner for your cooling system success.

Before placing an order, ask yourself:

Is the cooling capacity accurately calculated?

Does the design suit my climate and water conditions?

Are energy efficiency and maintenance costs optimized?

Is the manufacturer experienced and reliable?

If the answer is yes, you’re ready to move forward.

Choosing the right industrial cooling tower is about understanding your process, your environment, and your long-term operating goals. With the right design and a trusted manufacturer like Mach Cooling, your cooling system will quietly and efficiently support your plant for decades to come.

Top 6 Cooling Tower Manufacturers in Singapore in 2026: Industry Leaders & Market Insights

Top 10 Cooling Tower Manufacturers in The Philippines in 2026: Industry Leaders & Market Insights

The World’s Leading Cooling Tower Manufacturers: Top 8 Rankings

Which Is Better? Cooling Tower Vs Evaporative Cooler for Industrial Use

Smart Cooling Tower System Controls: IoT And Remote Monitoring

How To Choose The Right Cooling Tower for A Thermal Power Plant

Customized Cooling Tower Optimization Solutions for Industrial Plants

Cooling Tower Sound Test: Identifying Noise Issues And Solutions