We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

Cooling towers are critical heat rejection devices used in industrial processes, power plants, HVAC systems, and marine applications. Correctly calculating cooling tower capacity ensures stable operation, energy efficiency, and controlled cooling tower water consumption. This article provides a complete and practical explanation of how cooling tower capacity is calculated, covering formulas, temperature parameters, water usage, and system components such as the cooling tower water pump.

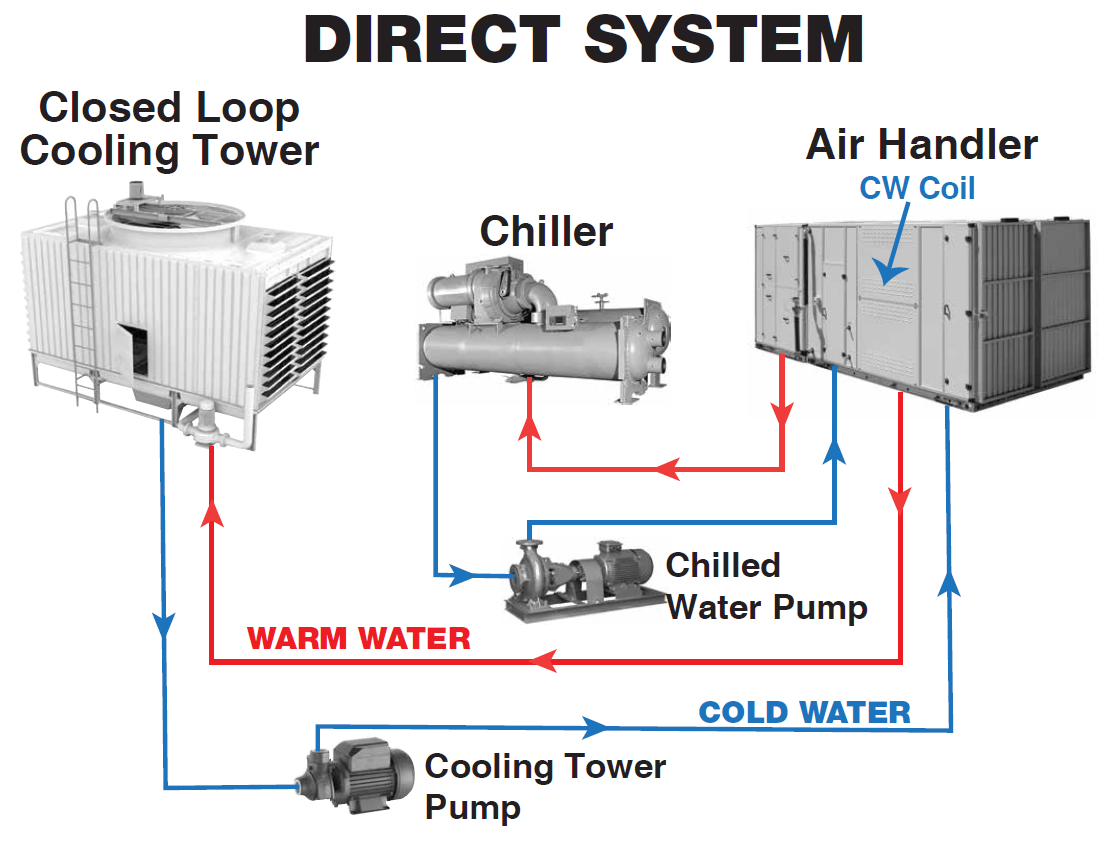

All explanations apply to common designs including water cooling towers, closed loop cooling towers, chilled water cooling tower systems, and sea water cooling towers.

This guide also references solutions provided by Mach Cooling (https://www.machcooling.com/), a professional manufacturer of cooling tower systems.

Cooling tower capacity refers to the amount of heat a cooling tower can remove from circulating water within a given time. It is typically expressed in:

Tons of refrigeration (TR)

Kilowatts (kW) of heat rejection

Water flow rate (m³/h or GPM) combined with temperature difference

A properly sized water cooled tower ensures efficient heat dissipation, protects equipment, and minimizes water and energy waste.

A water cooling tower system removes heat by spraying warm water over fill media while air flows through the tower. A small portion of water evaporates, carrying heat away and lowering the bulk water temperature.

Key components include:

Water distribution system

Fill media

Fan and air inlet louvers

Cold water basin

Cooling tower water pump

| Type | Description | Typical Application |

|---|---|---|

| Blowdown water cooling tower (open loop) | Water directly contacts air, requiring blowdown | Industrial processes |

| Closed loop cooling tower | Process fluid isolated in coils | Clean or sensitive systems |

| Chilled water cooling tower | Rejects heat from chiller condenser loop | HVAC systems |

| Sea water cooling tower | Uses seawater or marine makeup | Coastal & offshore plants |

Understanding temperature is essential when calculating capacity.

Hot Water Temperature (Entering Water)

Temperature of water entering the cooling tower from the process.

Cold Water Temperature (Leaving Water)

Temperature after heat rejection.

Wet Bulb Temperature

Lowest theoretical temperature achievable by evaporation and the main environmental limit.

Range = Hot Water Temp − Cold Water Temp

Approach = Cold Water Temp − Wet Bulb Temp

Smaller approach values require larger towers and higher airflow.

Cooling Capacity (BTU/hr) = Water Flow (GPM) × 500 × ΔT (°F)

Where:

500 = constant for water (density × specific heat)

ΔT = temperature range

Capacity (TR) = BTU/hr ÷ 12,000

Assume:

Flow rate = 400 GPM

Hot water = 95°F

Cold water = 85°F

ΔT = 10°F BTU/hr = 400 × 500 × 10 = 2,000,000 Capacity = 2,000,000 ÷ 12,000 ≈ 167 TR

The required cooling tower capacity is approximately 167 tons.

Cooling tower water usage comes from three sources:

Evaporation is directly related to heat load:

Evaporation (GPM) ≈ 0.001 × Circulating Flow × Range

Blowdown controls dissolved solids concentration. Higher cycles of concentration reduce blowdown but require better water treatment.

Small droplets carried out with exhaust air, minimized by drift eliminators.

The cooling tower water pump must deliver:

Required flow rate

Adequate head to overcome piping, fill, and heat exchanger resistance

Improper pump sizing can reduce effective cooling capacity even if the tower itself is correctly sized.

In a cooling tower chilled water system, the tower rejects heat from the chiller condenser. Lower condenser water temperature improves chiller efficiency and reduces overall energy consumption.

Sea water cooling towers require:

Corrosion-resistant materials

Consideration of fouling and scaling

Adjusted capacity due to higher salinity

Despite these challenges, capacity calculations still rely on flow rate and temperature range.

| Parameter | Typical Value |

|---|---|

| Water flow rate | 50–2000 m³/h |

| Hot water temperature | 30–50°C |

| Cold water temperature | 25–35°C |

| Wet bulb temperature | Site-specific |

| Approach | 3–8°C |

| Cooling capacity | 50–5000+ TR |

Accurate calculations must be matched with high-quality equipment. Mach Cooling (https://www.machcooling.com/) provides:

Water cooling towers and water cooled towers

Closed loop and blowdown water cooling towers

Chilled water cooling tower systems

Customized solutions for industrial and marine applications

Their engineering support ensures cooling tower capacity calculations align with real operating conditions.

Cooling tower capacity calculation is based on heat load, water flow rate, temperature range, and ambient wet bulb temperature. By understanding these fundamentals and accounting for cooling tower water consumption, pump performance, and system design, engineers can select an efficient and reliable cooling solution.

Whether designing a water cooling tower system, a closed loop cooling tower, or a sea water cooling tower, accurate capacity calculation combined with professional manufacturing expertise is the key to long-term performance and efficiency.

Top 6 Cooling Tower Manufacturers in Singapore in 2026: Industry Leaders & Market Insights

Top 10 Cooling Tower Manufacturers in The Philippines in 2026: Industry Leaders & Market Insights

The World’s Leading Cooling Tower Manufacturers: Top 8 Rankings

Which Is Better? Cooling Tower Vs Evaporative Cooler for Industrial Use

Smart Cooling Tower System Controls: IoT And Remote Monitoring

How To Choose The Right Cooling Tower for A Thermal Power Plant

Customized Cooling Tower Optimization Solutions for Industrial Plants

Cooling Tower Sound Test: Identifying Noise Issues And Solutions