We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

Cooling towers are critical assets in industrial and commercial cooling systems. From power plants and chemical factories to HVAC systems and data centers, cooling towers operate continuously under demanding mechanical conditions. But what protects these massive systems when something starts to go wrong?

The answer is often a small but powerful device: the cooling tower vibration switch.

In this complete guide, we’ll explain what a cooling tower vibration switch is, how it works, why it matters, and how leading manufacturers like Mach Cooling integrate vibration protection to ensure long-term reliability and safety.

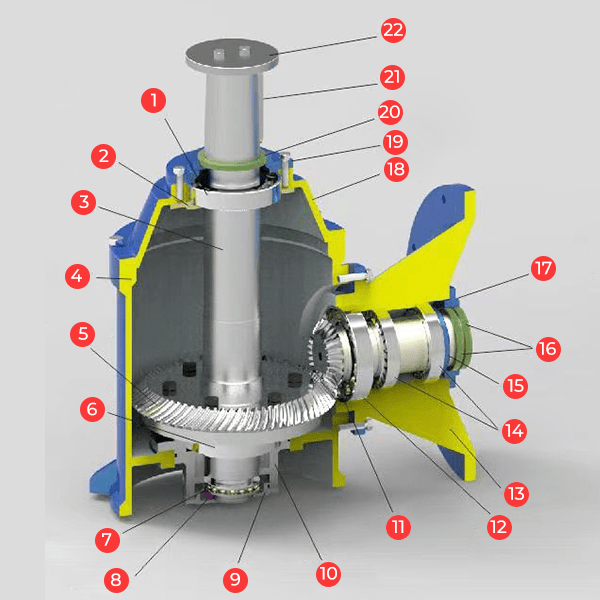

Cooling towers rely on rotating equipment—fans, motors, shafts, and gearboxes—that operate at high speed for extended periods. Over time, vibration is unavoidable. What matters is how early you detect abnormal vibration before it turns into equipment failure.

A vibration switch works like an early warning system. Just as a smoke detector alerts you before a fire spreads, a vibration switch alerts operators before mechanical damage becomes catastrophic.

A cooling tower vibration switch is a protective device designed to detect excessive vibration in rotating cooling tower components. When vibration exceeds a preset limit, the switch activates an alarm or shuts down the equipment automatically.

In simple terms, it listens to the “heartbeat” of your cooling tower—and reacts when something sounds wrong.

Ignoring vibration is risky. Excessive vibration often indicates underlying mechanical problems that can escalate rapidly.

Fan blade imbalance due to dirt, ice, or damage

Motor or shaft misalignment

Bearing wear or lubrication failure

Gearbox defects

Loose structural connections

Without protection, these issues can lead to fan collapse, motor burnout, or even tower structural damage.

Inside the vibration switch is a mechanical or electronic sensing mechanism. When vibration exceeds the allowable limit, the internal mechanism moves beyond its calibrated range and triggers an electrical contact.

That signal can:

Sound an alarm

Stop the fan motor

Notify a PLC or control system

Fast action is the key to preventing damage.

Mechanical vibration switches are rugged, simple, and ideal for harsh environments.

Electronic vibration switches offer higher sensitivity, digital adjustment, and monitoring capabilities.

Both types are commonly used in industrial cooling towers.

This is the heart of the device. It detects motion and converts vibration into a mechanical or electrical signal.

The housing is typically made from aluminum alloy or stainless steel, designed to resist moisture, corrosion, and temperature fluctuations common in cooling tower environments.

These allow the switch to integrate seamlessly with alarms, control panels, and automated shutdown systems.

Correct installation is essential for accurate vibration detection.

This is the most common mounting point. Fan imbalance and bearing issues show up here first.

For large industrial cooling towers, vibration switches may also be installed near gearboxes or load-bearing frames.

A vibration switch can prevent:

Fan blade breakage

Motor shaft damage

Gearbox failure

The cost of prevention is minimal compared to emergency repairs.

Sudden mechanical failures can endanger personnel and halt operations. Vibration switches provide automatic protection even when operators aren’t present.

Cooling tower vibration switches are widely used in:

Induced draft cooling towers

Forced draft cooling towers

Counterflow and crossflow cooling towers

They are especially critical in high-load and continuous-duty applications.

It’s important to understand the difference:

A vibration switch reacts when limits are exceeded.

A vibration sensor continuously measures and records vibration data.

Many advanced cooling systems use both—sensors for monitoring, switches for protection.

Proper calibration is crucial.

Too sensitive → false trips

Not sensitive enough → delayed shutdown

Thresholds should be set based on fan size, operating speed, structure rigidity, and manufacturer recommendations.

Experienced cooling tower suppliers like Mach Cooling provide guidance to ensure optimal settings.

Typical issues include:

Frequent shutdowns caused by fan imbalance

No response due to wiring or contact failure

Delayed action caused by improper calibration

Most problems can be resolved through correct installation and routine inspection.

To ensure long-term reliability:

Inspect mounting bolts regularly

Test switch response during scheduled maintenance

Record vibration events for trend analysis

Preventive maintenance extends the life of both the switch and the cooling tower.

When selecting a vibration switch, consider:

Industrial-grade durability

Environmental protection rating

Compatibility with control systems

Not all cooling tower manufacturers treat vibration protection equally. Leading suppliers design towers with vibration monitoring in mind—not as an afterthought.

At https://www.machcooling.com/, Mach Cooling focuses on system reliability from the design stage. Cooling towers are engineered to support vibration protection devices that enhance safety, reduce downtime, and extend equipment life.

This integrated approach ensures customers receive not just a cooling tower—but a dependable long-term cooling solution.

A cooling tower vibration switch may be small, but its impact is enormous. It protects critical equipment, improves safety, and prevents costly downtime. In today’s industrial environment, vibration protection is not optional—it’s essential.

If you’re planning a new cooling tower or upgrading an existing one, choose manufacturers like Mach Cooling who understand that true reliability is built into the system from day one.

Top 6 Cooling Tower Manufacturers in Singapore in 2026: Industry Leaders & Market Insights

Top 10 Cooling Tower Manufacturers in The Philippines in 2026: Industry Leaders & Market Insights

The World’s Leading Cooling Tower Manufacturers: Top 8 Rankings

Which Is Better? Cooling Tower Vs Evaporative Cooler for Industrial Use

Smart Cooling Tower System Controls: IoT And Remote Monitoring

How To Choose The Right Cooling Tower for A Thermal Power Plant

Customized Cooling Tower Optimization Solutions for Industrial Plants

Cooling Tower Sound Test: Identifying Noise Issues And Solutions