We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-06 Origin: Site

Introduction: Why HVAC Efficiency Matters

Have you ever wondered how massive buildings stay cool even when outdoor temperatures soar? The secret often lies in smart cooling solutions — and closed loop cooling towers are one of them.

In modern HVAC (Heating, Ventilation, and Air Conditioning) systems, cooling towers are essential for rejecting heat. But not all cooling towers are created equal — closed loop systems bring advantages that fit perfectly with today’s energy efficiency goals. Whether it’s a commercial high-rise or a data center running 24/7, closed loop cooling is quietly doing its job.

This article dives deep into the real-world applications of closed loop cooling towers in HVAC systems — how they work, where they shine, and why engineers and facility managers are increasingly choosing them.

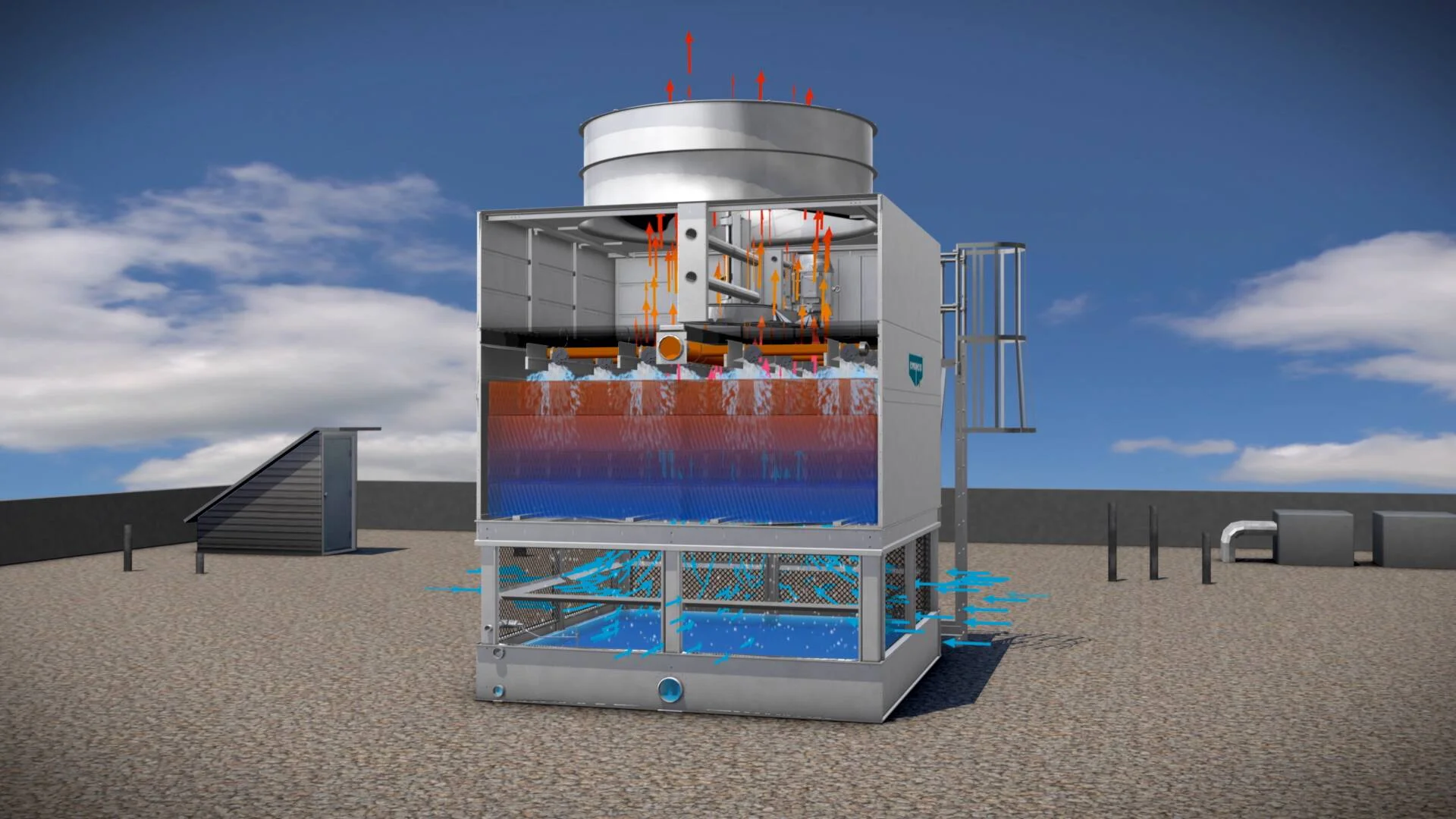

A closed loop cooling tower is a heat rejection device designed to cool water or thermal fluid that’s been heated by HVAC or mechanical processes — but it does so without exposing the fluid directly to the outside air. Instead, the heated fluid runs through sealed coils or heat exchangers, and a separate water loop removes the heat into the atmosphere.

Think of it like a thermos bottle with a cooling fan — the fluid inside never touches the outside world, but heat still escapes efficiently.

Most closed loop cooling tower systems include:

Sealed coils or heat exchanger bundles

Circulating pumps

Fans for air movement

Control instrumentation

Water distribution system around coils

Together, these components move heat from the HVAC system to the outside environment — quietly and continuously.

At the heart of every cooling tower is heat transfer. In a closed loop setup:

Warm fluid returns from the HVAC system.

It flows through a sealed coil inside the cooling tower.

External water sprayed over the coil absorbs heat.

A fan blows air through the tower, removing the absorbed heat.

The cooled fluid then heads back to the HVAC system.

Since the HVAC fluid never mixes with outside water, contamination and corrosion risks drop dramatically.

The difference might seem subtle, but it’s important:

Open Loop Tower: Exposes water directly to air, leading to evaporation and potential contamination.

Closed Loop Tower: Keeps fluid inside sealed coils — safer, cleaner, and often more efficient.

Closed loop systems are ideal when fluid purity matters or where environmental regulations limit water usage.

Closed loop cooling towers have broad utility. Here’s where they really shine:

High-rises, corporate headquarters, and multi-tenant offices rely on closed loop cooling towers to maintain year-round comfort. Occupants expect predictable cooling, and closed loop systems deliver stability while minimizing maintenance hassles.

Heat loads in factories, manufacturing lines, and data centers are intense. Servers and machinery generate tremendous heat continuously. Closed loop cooling towers provide reliable thermal management with minimal downtime. Often, these systems include redundant pumps and backup controls for uninterrupted operation.

Hospitals, labs, and research facilities cannot tolerate temperature swings. Sensitive equipment and patient areas require consistent, clean cooling. Closed loop cooling towers offer sanitary, sealed operation that’s perfect for such environments.

University buildings, dormitories, and teaching hospitals often use centralized HVAC systems. Closed loop cooling towers efficiently serve multiple buildings while maintaining water conservation and consistent cooling.

Large apartment complexes and residential towers benefit from closed loop designs due to their energy efficiency, low maintenance, and ability to maintain comfort across multiple units.

Why are these systems gaining popularity? Let’s break down the main benefits.

Closed loop cooling towers reduce energy consumption in HVAC systems, often resulting in significant cost savings over time. Better heat transfer and minimized energy loss mean lower operating costs.

It’s like driving a fuel-efficient car — you may pay more upfront, but the long-term savings are real.

Open loop systems lose water through evaporation and blowdown. Closed loop designs recycle fluid internally, drastically reducing water use — especially important in regions with water scarcity or strict environmental regulations.

Sealed systems experience fewer problems with scaling, corrosion, or biofouling. This means:

Longer equipment life

Fewer unscheduled shutdowns

Reduced maintenance costs

Think of it as a car that never needs oil changes — smoother operation and less hassle.

Choosing the right system requires careful planning.

Consider these factors when selecting a cooling tower:

Total heat load of your HVAC system

Seasonal temperature variations

Water quality and local climate

Future expansion plans

An undersized tower struggles, while an oversized one wastes space and money.

Quality matters. Manufacturers like Mach Cooling (https://www.machcooling.com/) provide advanced closed loop solutions tailored for HVAC applications. Their designs focus on durability, efficiency, and simplified maintenance — all key to long-term performance.

Even the best systems can encounter issues.

Mineral buildup can occur over time. Routine chemical treatment and inspections keep surfaces clean and maintain heat transfer efficiency.

Looking ahead, cooling towers are evolving:

Smart control systems dynamically adjust airflow

AI-driven predictive maintenance improves uptime

Hybrid cooling solutions combine air and water cooling

Eco-friendly refrigerants and fluids reduce environmental impact

Closed loop cooling towers fit perfectly into these trends, offering adaptability and efficiency.

Closed loop cooling towers are a cornerstone of modern HVAC systems. From office towers to hospitals, from water savings to energy efficiency, these systems are quiet but powerful heroes of building comfort.

For reliable, efficient, and low-maintenance cooling, especially where fluid purity and environmental considerations are crucial, closed loop cooling towers — like those from Mach Cooling — are a game changer.

If you’re considering upgrading your building’s cooling system, a closed loop solution is worth serious consideration.

Top 6 Cooling Tower Manufacturers in Singapore in 2026: Industry Leaders & Market Insights

Top 10 Cooling Tower Manufacturers in The Philippines in 2026: Industry Leaders & Market Insights

The World’s Leading Cooling Tower Manufacturers: Top 8 Rankings

Which Is Better? Cooling Tower Vs Evaporative Cooler for Industrial Use

Smart Cooling Tower System Controls: IoT And Remote Monitoring

How To Choose The Right Cooling Tower for A Thermal Power Plant

Customized Cooling Tower Optimization Solutions for Industrial Plants

Cooling Tower Sound Test: Identifying Noise Issues And Solutions