We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-07 Origin: Site

Water is the heartbeat of every cooling tower system. Yet many operators underestimate how quickly poor water quality can drag performance down. Dirt, debris, biological growth, and process contaminants quietly circulate through the system, reducing efficiency and accelerating wear.

That’s why cooling tower filtration plays such a vital role in water quality management. Think of filtration as the immune system of a cooling tower—it continuously removes harmful elements before they cause serious damage.

Clean water isn’t just about appearances. It directly impacts how well a cooling tower performs and how long it lasts.

Suspended solids coat heat transfer surfaces like a thin blanket. Even a small buildup can significantly reduce thermal efficiency, forcing fans and pumps to work harder. The result? Higher energy consumption and reduced cooling capacity.

Poor water quality accelerates corrosion, scaling, and fouling. Over time, this leads to clogged spray nozzles, damaged fill media, and degraded basins. Clean water, on the other hand, protects equipment and extends service life.

Cooling tower filtration is the mechanical removal of contaminants from circulating water. Unlike chemical treatment, which controls scale and bacteria, filtration physically removes particles before they settle or react.

Filtration works much like a household water filter. Water flows through a filtering medium, while dirt and debris are captured and removed from circulation.

Chemical treatment and filtration are partners, not competitors. Filtration reduces the contaminant load, allowing chemicals to work more efficiently and lowering overall chemical consumption.

Dust, sand, rust particles, and airborne debris constantly enter open cooling systems. These solids settle in basins and clog heat transfer surfaces.

Warm, nutrient-rich water is ideal for algae and bacteria. Once biofilm forms, it becomes difficult to control without aggressive treatment.

In industrial environments, oils and chemical residues can enter cooling water, severely degrading water quality and heat transfer performance.

Different systems require different filtration approaches. Selecting the right type is critical.

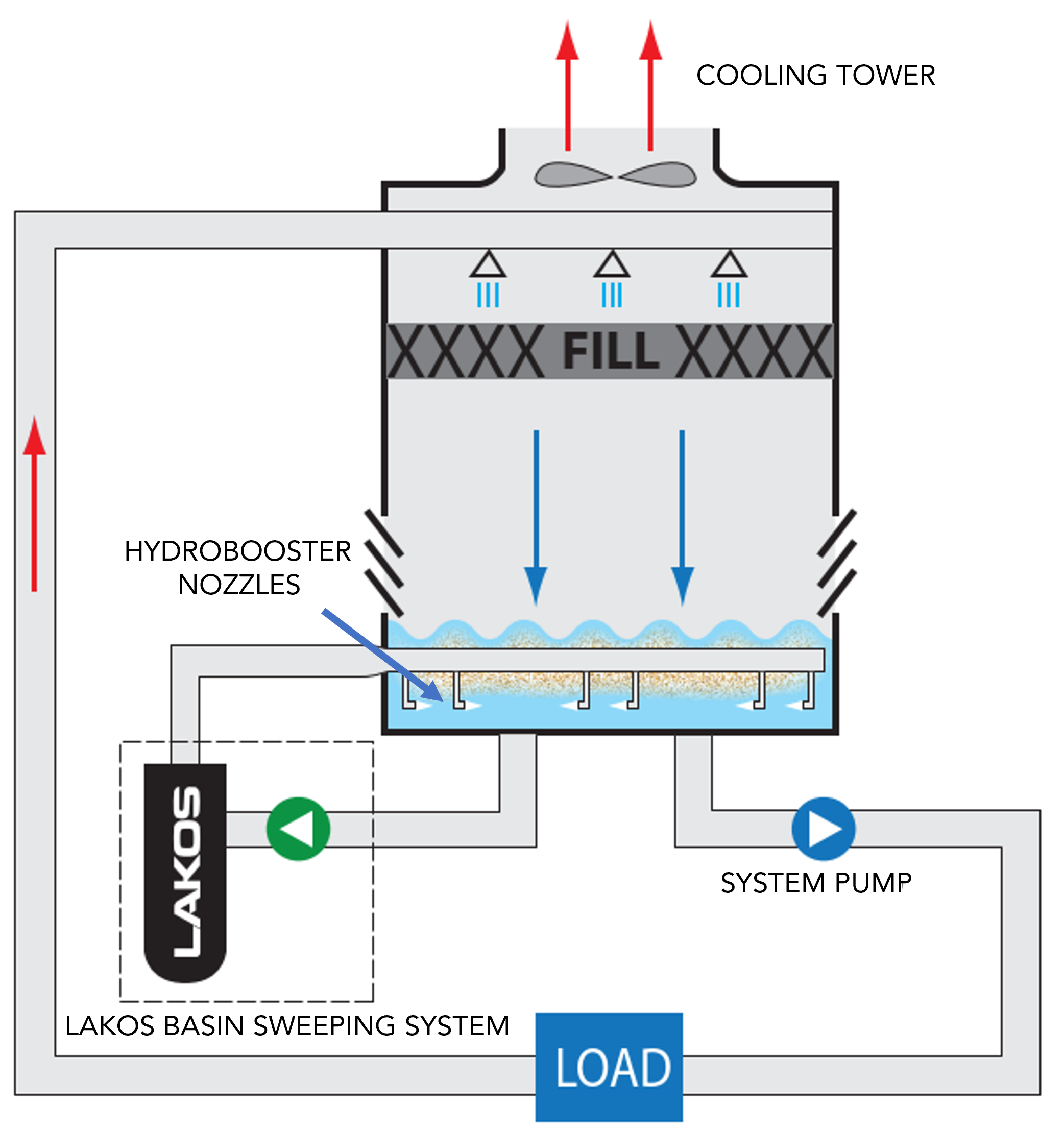

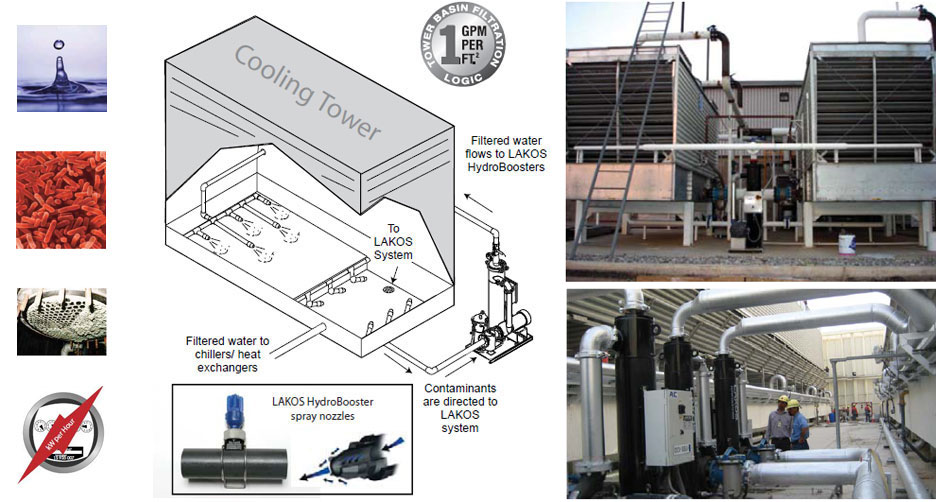

Side stream filtration continuously treats a portion of circulating water—usually 5% to 15%—maintaining consistent water quality.

Sand filters are simple, proven, and cost-effective. They trap particles as water passes through layers of sand.

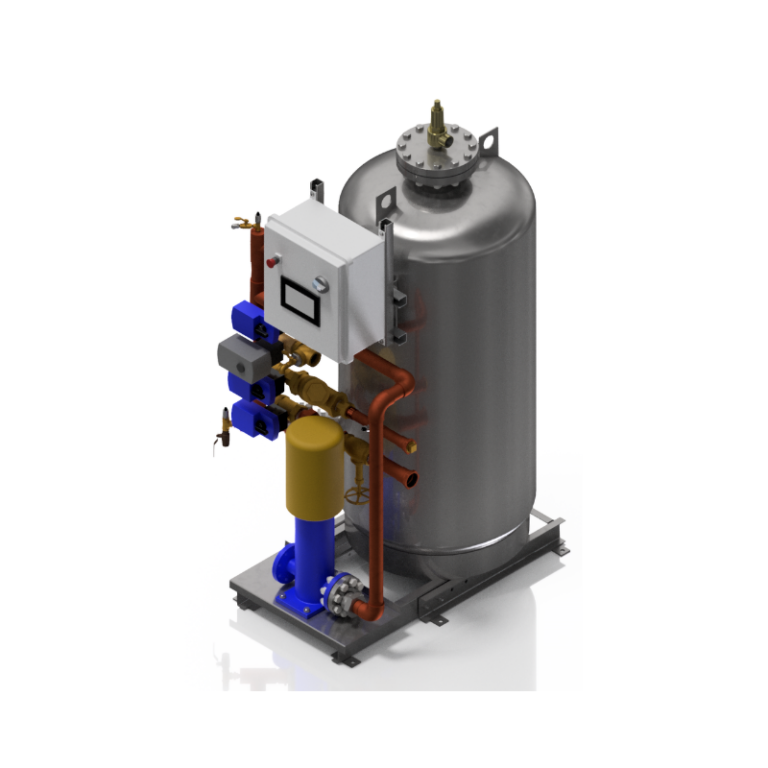

Multimedia filters use multiple layers of filtration media, allowing them to capture finer particles and handle higher contamination loads.

In full flow systems, all circulating water passes through the filter. This provides excellent cleanliness but requires careful system design and higher initial investment.

These advanced filters automatically remove captured solids without interrupting system operation, making them ideal for modern HVAC and industrial systems.

By continuously removing suspended solids, filtration lowers turbidity and reduces organic matter. Cleaner water leads to better heat transfer, reduced biological growth, and more stable system operation. It’s a simple concept with powerful results.

When heat transfer surfaces stay clean, cooling towers operate closer to their design efficiency. Fans, pumps, and chillers consume less power, often resulting in noticeable energy savings over time.

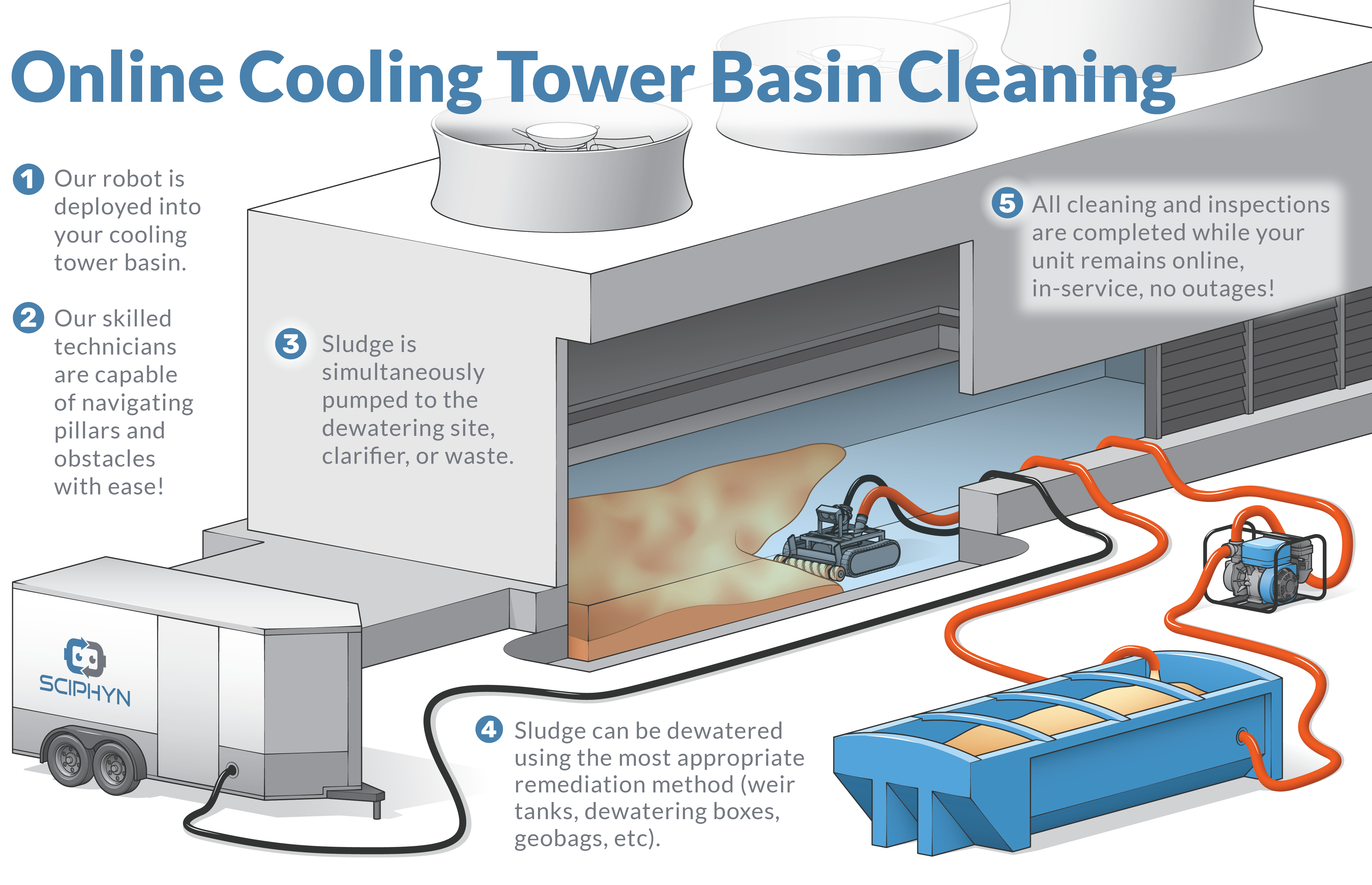

Filtration dramatically reduces maintenance demands. Basins stay cleaner, nozzles clog less frequently, and fill media lasts longer. Maintenance teams can shift focus from reactive cleaning to proactive system optimization.

While filtration does not disinfect water, it removes the nutrients bacteria need to thrive. When combined with proper chemical treatment, filtration significantly reduces the risk of Legionella and other waterborne pathogens.

Industrial cooling towers often face heavier contamination loads and benefit from robust, high-capacity filtration systems. HVAC cooling towers, especially in urban or dusty environments, also gain efficiency and reliability from well-designed filtration.

Selecting the right system depends on several factors:

Water quality and solids concentration

Cooling tower size and flow rate

Operating hours

Maintenance capabilities

A tailored approach always delivers better results than a generic solution.

Filtration works best when it is considered during the cooling tower design stage. Experienced manufacturers ensure proper integration, balanced hydraulics, and easy maintenance access.

As a professional cooling tower manufacturer, Mach Cooling understands that effective water quality management starts with smart system design. By supporting filtration-friendly layouts and efficient water circulation, Mach Cooling helps customers achieve higher efficiency, lower operating costs, and longer equipment life.

Learn more at https://www.machcooling.com/.

The future of cooling tower filtration lies in automation, smart monitoring, and water-saving technologies. Intelligent filtration systems are becoming more efficient, easier to maintain, and better aligned with sustainability goals.

Cooling tower filtration is not an optional upgrade—it is a core component of effective water quality management. From improving efficiency and reducing maintenance to supporting health and safety goals, filtration delivers lasting value.

For reliable, high-performance cooling tower systems designed with water quality in mind, partnering with experienced manufacturers like Mach Cooling makes all the difference.

Top 10 Cooling Tower Manufacturers in Philippines in 2026: Industry Leaders & Market Insights

Top 6 Cooling Tower Manufacturers in Singapore in 2026: Industry Leaders & Market Insights

Top 10 Cooling Tower Manufacturers in The Philippines in 2026: Industry Leaders & Market Insights

The World’s Leading Cooling Tower Manufacturers: Top 8 Rankings

Which Is Better? Cooling Tower Vs Evaporative Cooler for Industrial Use

Smart Cooling Tower System Controls: IoT And Remote Monitoring

How To Choose The Right Cooling Tower for A Thermal Power Plant

Customized Cooling Tower Optimization Solutions for Industrial Plants