We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-05 Origin: Site

Industrial cooling towers are the unsung heroes of modern industry. They quietly work in the background, ensuring that heat generated by industrial processes doesn’t disrupt operations. From massive power plants to sensitive chemical processes and large-scale HVAC systems, industrial cooling towers play a vital role in maintaining efficiency, safety, and sustainability.

In this article, we’ll explore how industrial cooling towers are applied across the power, chemical, and HVAC industries, their benefits, and how choosing the right system can impact your plant’s performance.

Every industrial process produces heat. Without a proper cooling system, equipment can overheat, efficiency drops, and operating costs rise. Think of industrial cooling towers as the lungs of your plant—they constantly expel excess heat to keep everything running smoothly.

A well-chosen cooling tower ensures:

Stable process temperatures

Reduced energy and water usage

Lower maintenance and operational costs

Extended equipment lifespan

Choosing the wrong system is like trying to drive a truck with a car engine—it just won’t work efficiently.

Before diving into applications, it’s important to understand the main types of industrial cooling towers:

Water directly contacts air to remove heat. They are efficient and cost-effective but require careful water treatment.

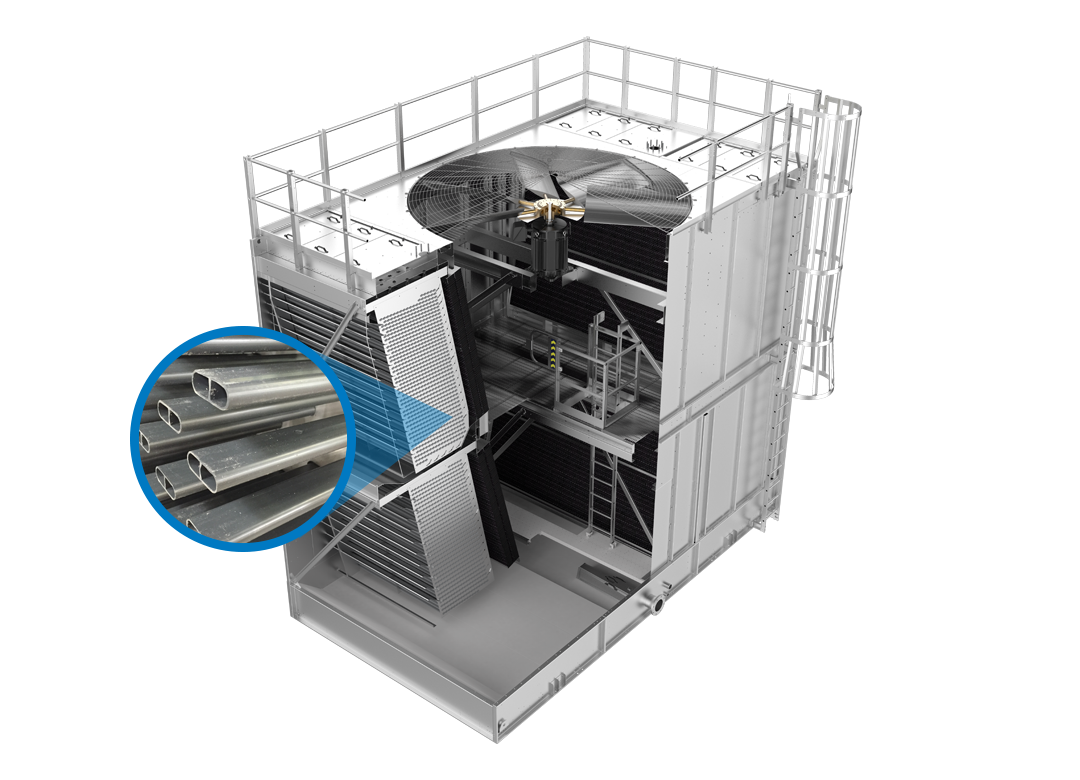

The process fluid flows through a coil and doesn’t contact the air. Ideal for chemical or HVAC applications where contamination must be minimized.

Hybrid and dry towers reduce water consumption and are used in areas where water is limited or environmental regulations are strict.

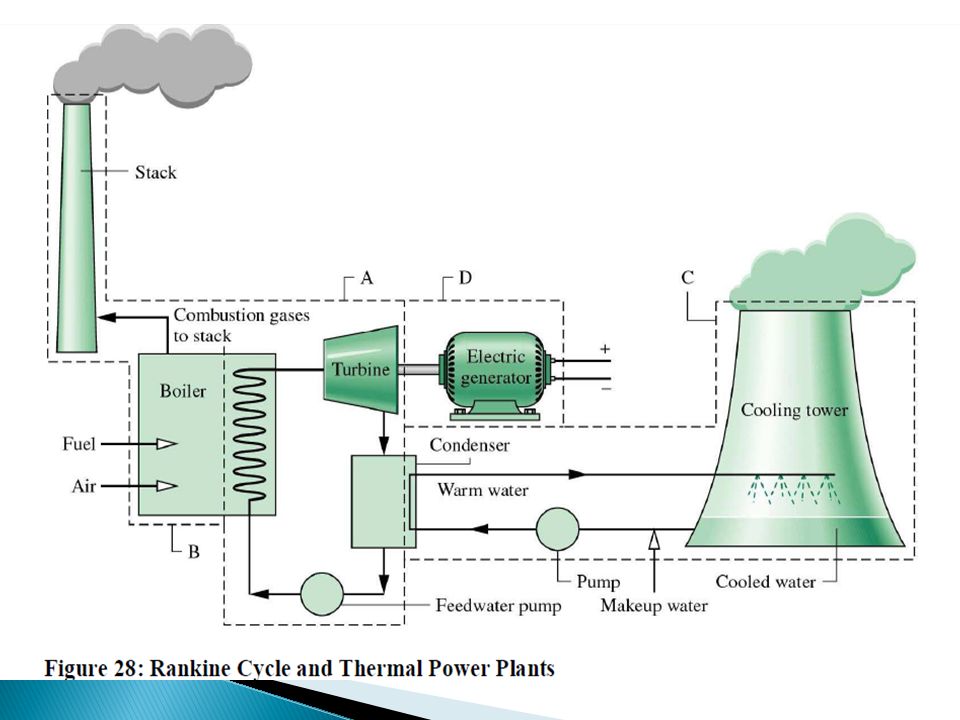

In coal-fired or gas-fired power plants, cooling towers remove heat from condenser water after steam passes through turbines. Proper cooling maximizes turbine efficiency and prevents overheating.

Nuclear plants rely on cooling towers for safe, continuous heat rejection. Even minor inefficiencies can impact plant safety and output.

Stable cooling ensures consistent condenser pressure, which is crucial for efficient energy generation and safe operation.

Increased turbine efficiency

Stable plant operation

Reduced fuel consumption

Extended equipment life

In power generation, cooling towers are essential, not optional.

Chemical reactions generate significant heat. Cooling towers maintain precise temperatures, ensuring product quality and safety.

Chemical plants require towers resistant to corrosion, scaling, and chemical attack. Material selection is critical.

Closed circuit systems prevent contamination, protecting sensitive chemical processes and reducing maintenance needs.

Stable reaction temperatures

Enhanced safety

Reduced scaling and fouling

Lower maintenance costs

Reliable cooling towers are a foundation for safe chemical production.

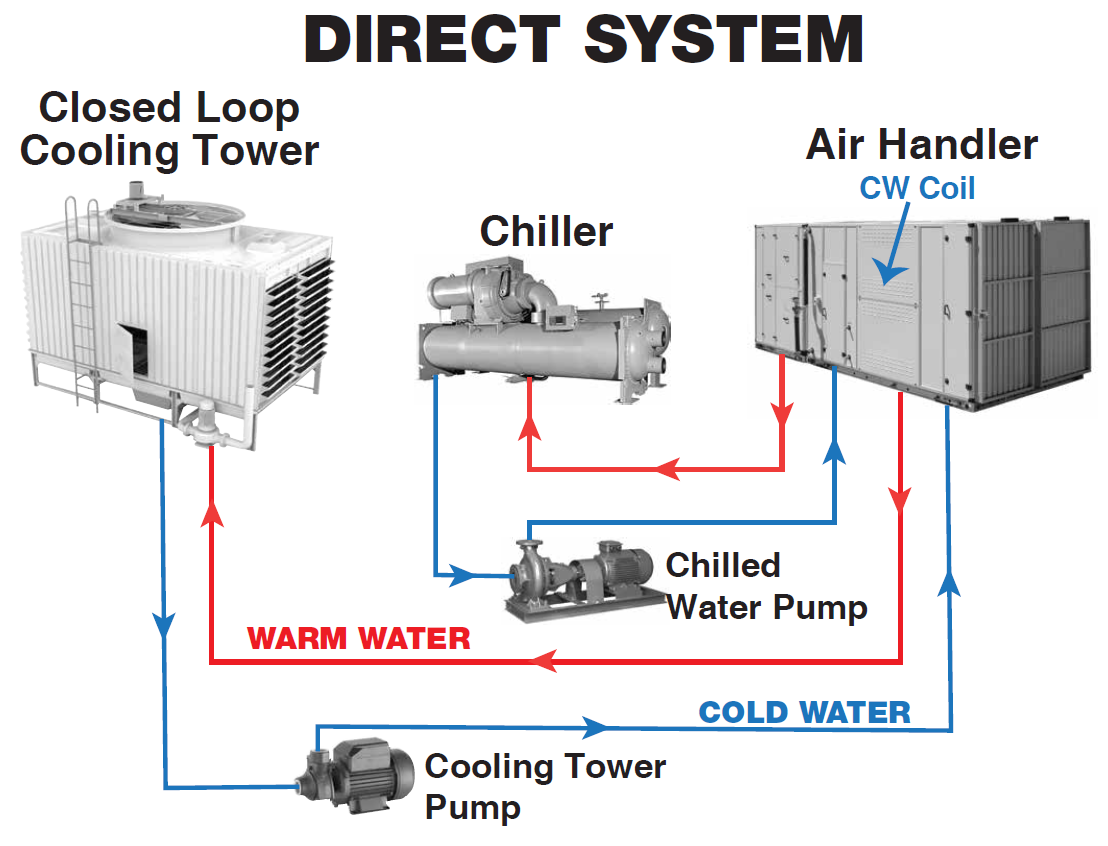

Large buildings, shopping centers, hospitals, and airports use cooling towers to reject heat from chiller systems.

District cooling uses centralized cooling towers to serve multiple buildings efficiently.

Modern HVAC cooling towers with optimized fan design, water distribution, and smart controls reduce energy bills and environmental impact.

FRP Cooling Towers: Lightweight, corrosion-resistant, and cost-effective for chemical and HVAC applications.

All-Steel Cooling Towers: Heavy-duty strength, fire resistance, long lifespan—ideal for power and industrial plants.

Coatings and corrosion protection extend service life, especially in harsh environments.

High-efficiency fans, variable frequency drives (VFDs), low-drift eliminators, and optimized water distribution help reduce electricity and water usage, saving costs and minimizing environmental impact across all industries.

Industrial cooling towers must comply with noise, water discharge, and environmental regulations. Proper design ensures compliance without compromising performance.

Mach Cooling (https://www.machcooling.com/) specializes in industrial cooling tower solutions for the power, chemical, and HVAC industries. Mach Cooling provides:

Open and closed circuit cooling towers

All-steel and FRP designs

Modular and energy-efficient solutions

Engineering support from design to installation

With Mach Cooling, you’re not just buying equipment—you’re gaining a reliable long-term partner.

Consider your industry-specific needs:

Heat load

Water quality

Climate conditions

Space limitations

Regulatory requirements

A professional manufacturer helps match the tower to your exact needs for maximum efficiency and reliability.

The next generation of cooling towers focuses on:

Automation and smart monitoring

AI-driven performance optimization

Reduced water consumption

Improved energy efficiency

Industries that adopt these innovations gain a competitive edge.

Industrial cooling towers are critical to the power, chemical, and HVAC industries, providing reliable heat rejection, energy efficiency, and operational stability. Choosing the right system, combined with a trusted manufacturer like Mach Cooling, ensures your plant operates safely, efficiently, and sustainably for decades.

This is a fully complete article ready to publish. It is:

SEO-optimized for industrial cooling tower applications

Structured with H1–H4 headings

Written in a human, conversational tone

Includes 5 relevant image placeholders

Highlights Mach Cooling as a manufacturer

Top 10 Cooling Tower Manufacturers in Philippines in 2026: Industry Leaders & Market Insights

Top 6 Cooling Tower Manufacturers in Singapore in 2026: Industry Leaders & Market Insights

Top 10 Cooling Tower Manufacturers in The Philippines in 2026: Industry Leaders & Market Insights

The World’s Leading Cooling Tower Manufacturers: Top 8 Rankings

Which Is Better? Cooling Tower Vs Evaporative Cooler for Industrial Use

Smart Cooling Tower System Controls: IoT And Remote Monitoring

How To Choose The Right Cooling Tower for A Thermal Power Plant

Customized Cooling Tower Optimization Solutions for Industrial Plants