We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

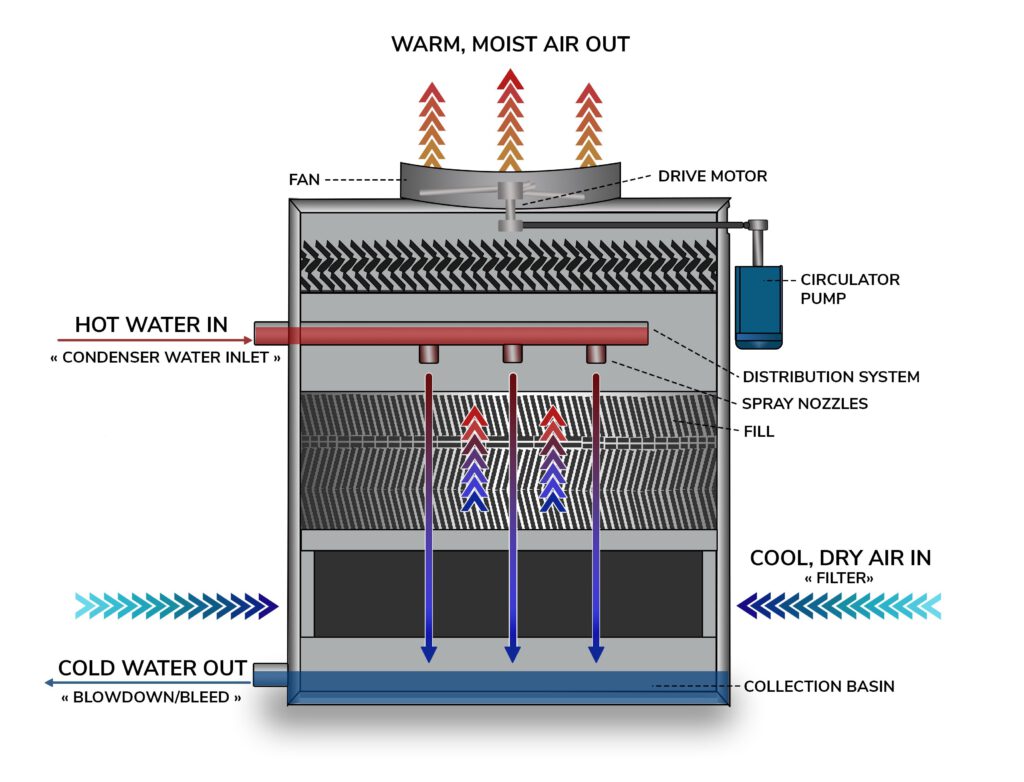

From the outside, a cooling tower looks calm and almost static. But step inside a cooling tower, and you’ll find a nonstop exchange of water, air, and heat happening every second. It’s a carefully engineered journey—one that starts with hot process water entering the tower and ends with cooled water collecting quietly in the basin below.

In this article, we’ll walk through the entire internal process from the hot water inlet to the cold water basin, explaining what happens at each stage and why every internal component matters. Think of it as a guided tour inside the cooling tower, explained in plain, human language.

At its core, a cooling tower is a heat rejection machine. But unlike a simple heat exchanger, it relies on evaporation, gravity, and airflow to do the job.

Inside the tower, water doesn’t just flow—it spreads, breaks apart, meets air, gives up heat, and then comes back together again. This internal choreography is what makes cooling towers so efficient and so widely used in power plants, industrial facilities, and HVAC systems.

If you only look at a cooling tower from the outside, you’re missing the most important part.

Understanding what happens inside a cooling tower helps you:

Improve cooling efficiency

Reduce water and energy waste

Prevent scaling, fouling, and corrosion

Extend the service life of internal components

That’s why experienced manufacturers like MACH Cooling focus heavily on internal design—not just the tower shell, but everything happening inside it.

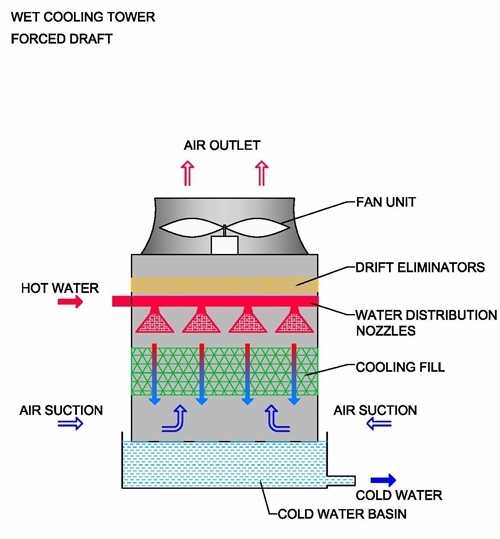

Before diving into details, let’s zoom out for a moment. The internal cooling process follows a simple path:

Hot water enters the cooling tower

Water is evenly distributed over the fill

Air flows through the falling water

Heat is removed by evaporation

Cooled water collects in the basin

Each step depends on the one before it. Miss one, and performance drops fast.

Hot water entering a cooling tower usually comes from:

Condensers in thermal or nuclear power plants

Industrial heat exchangers

HVAC chillers

This water carries unwanted heat that must be released to keep the process running smoothly.

Once the water reaches the cooling tower, it flows through inlet pipes or headers designed to handle high temperatures and continuous operation. A well-designed inlet system ensures smooth flow and prevents vibration, air entrainment, or uneven loading downstream.

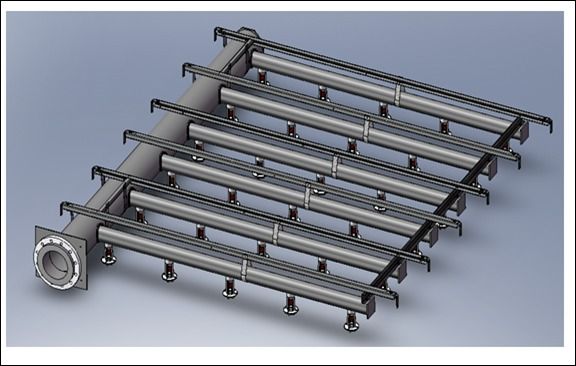

After entering the tower, hot water must be spread evenly across the fill. This is done using distribution headers and spray nozzles.

Their mission is simple but critical: deliver the same amount of water to every part of the fill.

Imagine watering a lawn—if one corner gets soaked and another stays dry, you’re wasting water and effort. The same logic applies inside a cooling tower.

Poor distribution leads to:

Reduced heat transfer

Dry zones inside the fill

Higher scaling risk

Uneven cooling performance

Professional manufacturers like MACH Cooling design distribution systems based on flow rate, tower size, and water quality to avoid these problems.

This is the heart of the cooling tower.

As water flows downward over the fill, air moves upward through it. A small portion of the water evaporates, and that evaporation pulls heat away from the remaining water.

It’s the same principle as sweating—except here, it’s happening on an industrial scale.

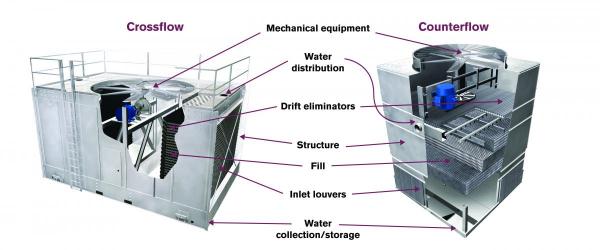

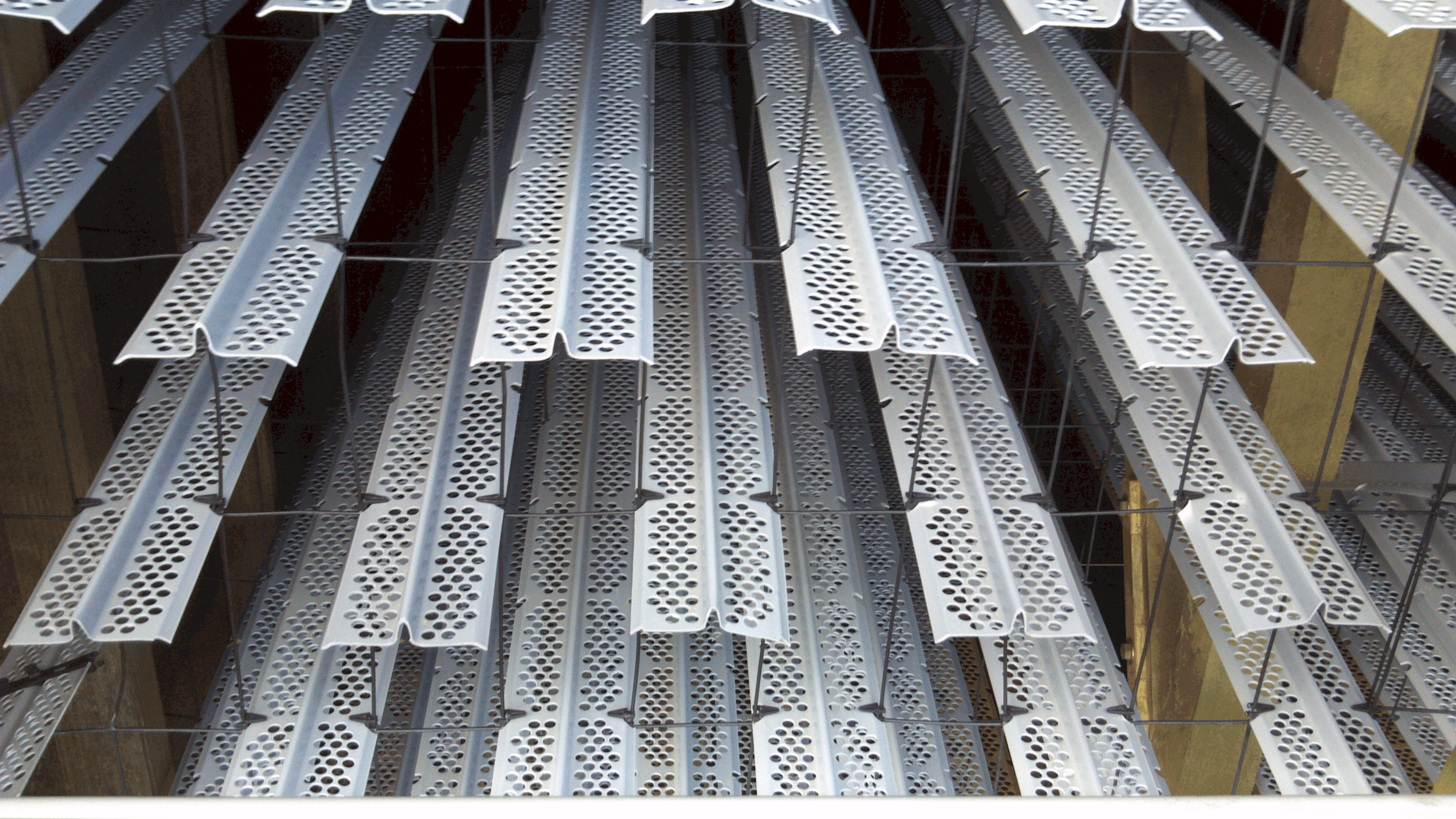

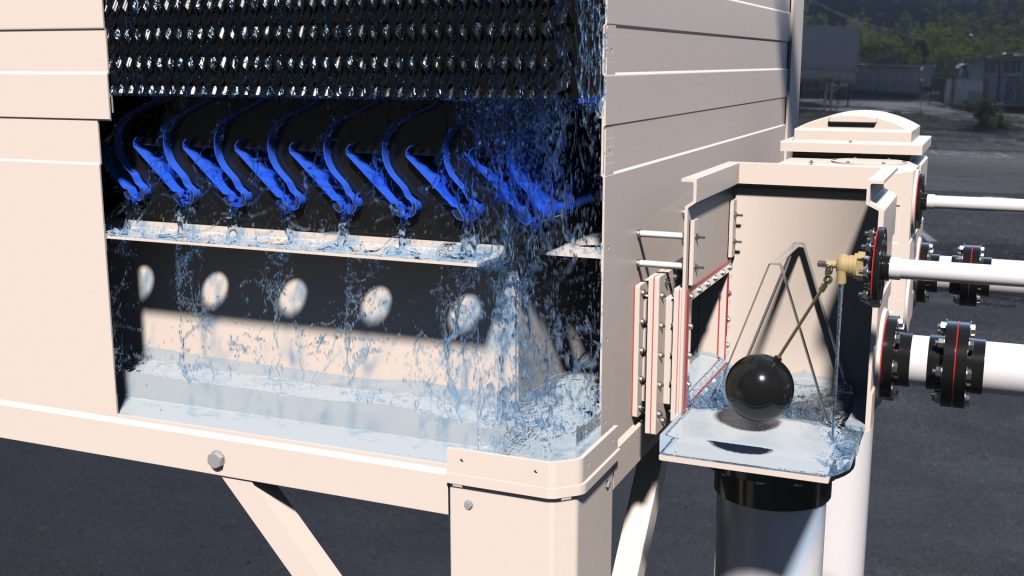

Splash fill breaks water into droplets by repeatedly splashing it across bars or grids. It’s tough, resistant to clogging, and ideal for applications with dirty or high-solids water.

Film fill spreads water into thin sheets over structured surfaces, maximizing contact area with air. It offers higher thermal efficiency but requires better water quality and treatment.

Air enters the cooling tower through louvers located at the base or sides. These louvers guide airflow while preventing splash-out, blocking debris, and reducing sunlight penetration that can promote algae growth.

As air rises through the fill, it absorbs heat and moisture from the falling water. This warm, humid air continues upward and exits the tower, while cooled water keeps moving downward.

The continuous meeting of air and water is what keeps the cooling process alive.

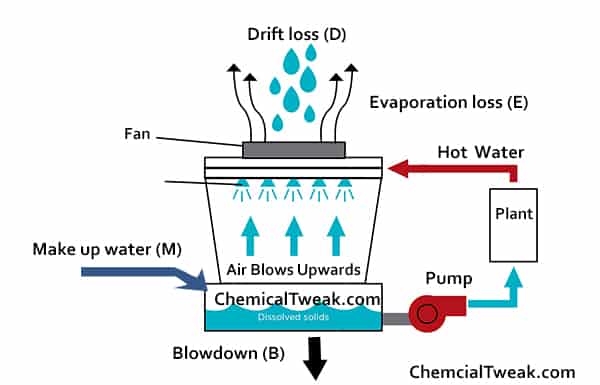

Not all water droplets fall straight down. Some try to escape with the outgoing air. Drift eliminators stop them.

These internal components force air to change direction several times, capturing water droplets and returning them to the tower. Good drift control means:

Lower water loss

Reduced chemical carryover

Better environmental compliance

After giving up its heat, cooled water drops into the cold water basin at the bottom of the tower. The basin acts as a collection and buffer zone, maintaining a stable water level for recirculation.

From the basin, cooled water is pumped back into the process—ready to absorb heat again. This closed-loop cycle repeats continuously during operation.

Internal inspections often reveal issues such as:

Scaling on fill surfaces

Blocked or damaged spray nozzles

Drift eliminator wear

Sediment buildup in the basin

Most of these problems trace back to poor internal design or inadequate maintenance.

As a professional cooling tower manufacturer, MACH Cooling designs internal components with efficiency and longevity in mind, including:

Optimized fill selection for different water qualities

Precision-engineered water distribution systems

High-performance drift eliminators

Basin designs that simplify cleaning and maintenance

More details can be found at https://www.machcooling.com/.

From the hot water inlet at the top to the cold water basin at the bottom, everything inside a cooling tower works together to remove heat as efficiently as possible.

When internal components are properly designed, installed, and maintained—and when the system is supplied by experienced manufacturers like MACH Cooling—the result is reliable cooling, lower operating costs, and long-term performance you can trust.

Cooling Tower for Sale – High Efficiency, Factory Direct Supply

Cooling Tower Capacity Vs Load: Matching Performance To Demand

Best Cooling Tower for Energy Efficiency And Low Operating Cost

Approach Temperature Vs Range in Cooling Towers: Key Differences

American Chillers And Cooling Tower Systems: Quality, Performance, And Reliability