We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-16 Origin: Site

Evaporation loss is an unavoidable but manageable part of cooling tower operation. In a water cooling tower, evaporation is the primary mechanism for heat rejection, yet excessive evaporation leads to high cooling tower water consumption, increased operating costs, and greater demand on the cooling tower water supply.

This article explains how to reduce evaporation loss in a water cooling tower system through proper design, operation, and water management strategies. The guidance applies to open water cooled towers as well as closed loop cooling towers, and reflects engineering best practices supported by MACH Cooling (https://www.machcooling.com/), a professional cooling tower manufacturer.

Evaporation loss occurs when a small portion of circulating water absorbs heat and changes into vapor. This process is essential for cooling, but excessive evaporation increases:

Cooling tower water consumption

Demand for cooling tower makeup water

Chemical treatment costs

Environmental impact

Typically, evaporation accounts for 70–80% of total cooling tower water loss, making it the primary focus of cooling tower water conservation.

The evaporation rate in a water cooled tower is directly related to:

System heat load

Temperature difference (range)

Ambient wet-bulb temperature

Higher heat loads require more evaporation, increasing makeup water demand.

A well-optimized cooling water tower design reduces unnecessary evaporation while maintaining thermal performance.

Important design elements include:

Efficient fill media for maximum heat transfer

Balanced air-to-water ratio

Uniform water distribution

Advanced designs offered by MACH Cooling improve heat rejection efficiency without increasing evaporation losses.

Proper control of cooling tower make up water is essential to prevent excessive water loss.

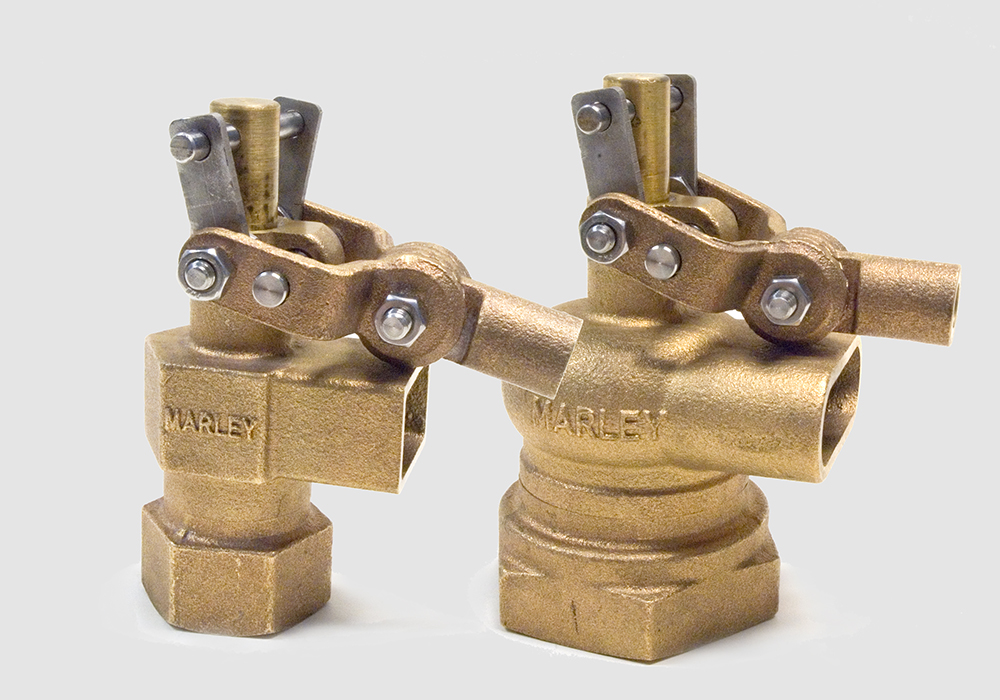

Use high-quality cooling tower make up water valves

Install reliable cooling tower makeup water float valves

Regularly inspect and calibrate valves to avoid overfilling

Accurate level control ensures makeup water is supplied only when needed.

Effective cooling tower water conservation includes:

Maintaining optimal cycles of concentration

Reducing unnecessary blowdown

Eliminating leaks and overflows

These measures directly lower overall cooling tower water consumption.

Lowering hot water inlet temperature reduces evaporation demand. Strategies include:

Improving heat exchanger performance

Reducing unnecessary system heat loads

Ensuring proper water flow distribution

Stable operation improves efficiency across the water cooling tower system.

Excessive circulation flow increases evaporation without improving cooling.

Best practices:

Keep flow rate within design limits

Balance distribution nozzles

Avoid pump oversizing

Controlled flow ensures effective cooling with minimal evaporation.

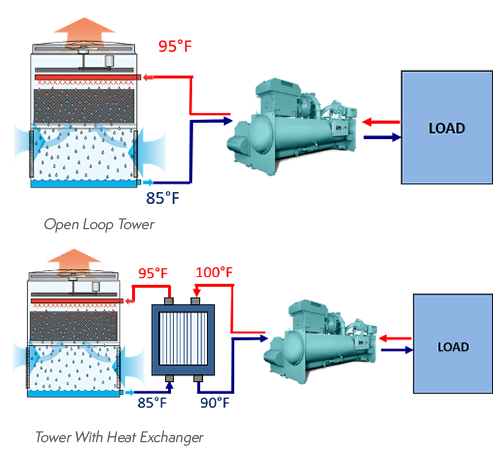

A closed loop cooling tower isolates process fluid from direct air contact, offering significant water conservation benefits:

Reduced evaporation loss

Lower contamination risk

Reduced makeup water demand

Closed loop systems are ideal for facilities seeking long-term cooling tower water conservation.

Accurate monitoring helps identify excessive evaporation.

Key parameters to track:

Makeup water flow rate

Blowdown volume

System heat load

Data-driven analysis supports continuous improvement in water efficiency.

A water balance helps quantify losses:

| Water Loss Type | Description |

|---|---|

| Evaporation | Heat rejection loss |

| Drift | Water carried with exhaust air |

| Blowdown | Controlled discharge |

| Leakage/Overflow | Preventable loss |

Understanding this balance allows targeted cooling tower water conservation actions.

| Measure | Benefit | Impact on Water Consumption |

|---|---|---|

| Optimize cycles of concentration | Reduced blowdown | Medium |

| Install precise makeup valves | Prevent overfilling | High |

| Improve tower design | Higher efficiency | Medium |

| Use closed loop cooling tower | Lower evaporation | High |

| Regular maintenance | Prevent hidden losses | High |

MACH Cooling (https://www.machcooling.com/) provides engineered solutions for reducing evaporation loss and improving overall cooling tower efficiency.

Advanced water cooling tower designs

High-efficiency water cooled towers

Reliable closed loop cooling tower solutions

Expertise in cooling tower water conservation and system optimization

MACH Cooling helps customers balance cooling performance with sustainable water usage.

While evaporation is essential for cooling, excessive loss is not. By optimizing cooling water tower design, controlling cooling tower makeup water, improving operational practices, and adopting closed loop cooling towers, facilities can significantly reduce evaporation loss.

Effective cooling tower water conservation lowers operating costs, reduces environmental impact, and ensures long-term system reliability. For customized solutions and expert support, visit MACH Cooling at:

Reducing evaporation loss is not about sacrificing performance—it’s about achieving smarter, more sustainable cooling.

Best Cooling Tower Manufacturers in Laos: Ranking The Top 10 in 2026

How To Reduce Maintenance Costs with Cooling Tower Scale & Corrosion Inhibitors

Meet The Top 5 Cooling Tower Manufacturers in Thailand for 2026

Top 8 Cooling Tower Manufacturers in Indonesia: Leading Innovators in 2026

Top 10 Cooling Tower Manufacturers in Philippines in 2026: Industry Leaders & Market Insights

Top 6 Cooling Tower Manufacturers in Singapore in 2026: Industry Leaders & Market Insights

Top 10 Cooling Tower Manufacturers in The Philippines in 2026: Industry Leaders & Market Insights