We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-15 Origin: Site

In any industrial or HVAC application, the performance of a water cooling tower depends not only on water circulation but also on how effectively air flows through the system. Air flow rate determines how much heat can be removed from hot circulating water and directly impacts energy efficiency, cooling stability, and cooling tower water use.

This article explains how to calculate air flow rate in a cooling tower, covering theory, formulas, and practical engineering considerations. It applies to various configurations, including water cooled tower, water cooling tower system, and closed loop cooling tower designs. The discussion also aligns with proven engineering practices adopted by professional manufacturers such as Mach Cooling (https://www.machcooling.com/).

A cooling tower removes heat by bringing warm water into contact with ambient air. As air passes through the tower:

Sensible heat is transferred from water to air

A small portion of water evaporates, removing latent heat

This process makes air flow the primary driver of cooling performance in any water cooling tower system.

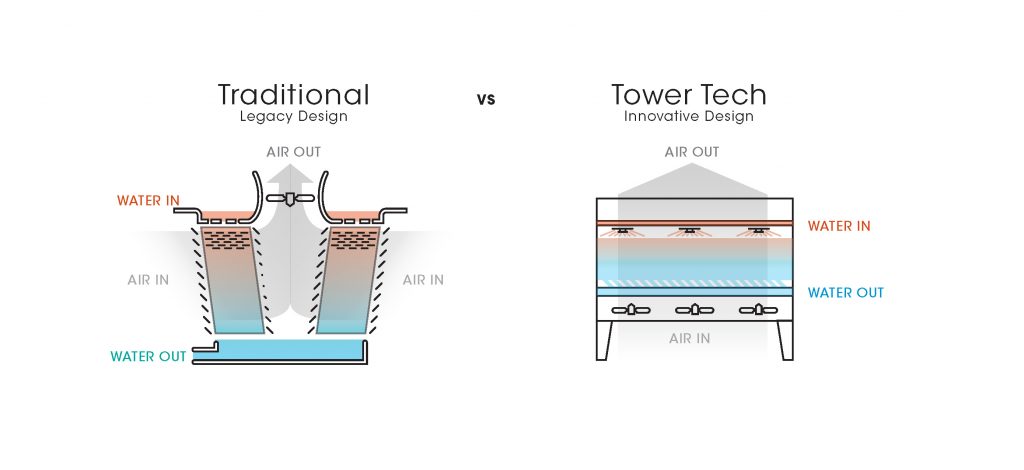

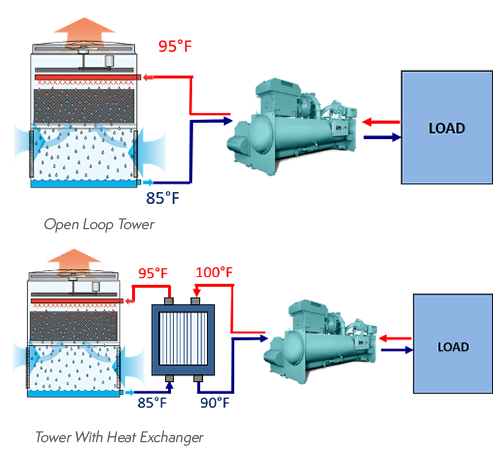

Different cooling tower designs influence how air flow is calculated:

Open water cooled tower: Air contacts water directly

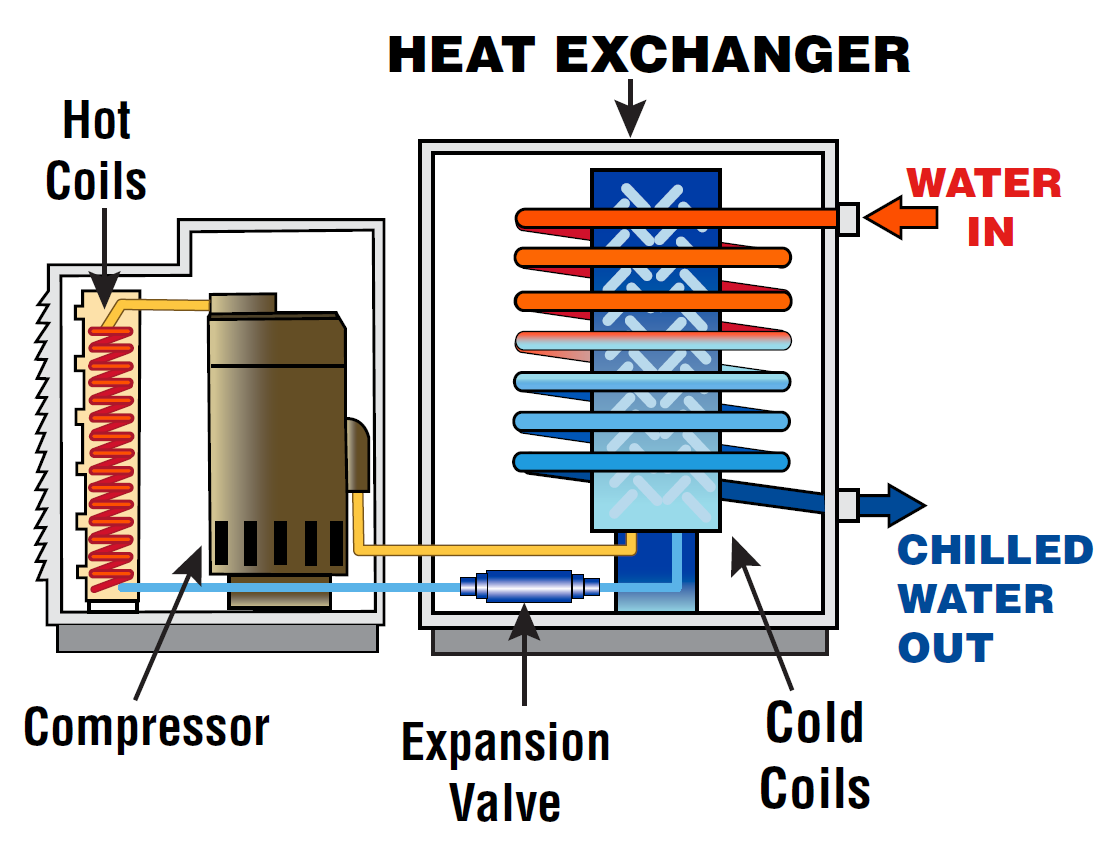

Closed loop cooling tower: Air cools a heat exchanger coil, isolating process water

Mechanical draft towers: Fans control air flow

Natural draft towers: Air flow driven by buoyancy

Regardless of type, airflow must be sufficient to meet the system’s thermal load.

If air flow is too low:

Water outlet temperature rises

Cooling capacity drops

Equipment may overheat

If air flow is too high:

Fan power consumption increases

Operating costs rise

Excessive evaporation increases cooling tower water use

Correct air flow ensures a balance between performance and energy efficiency.

Air flow also affects:

Cooling tower water supply requirements

Evaporation losses

Drift and blowdown rates

Therefore, airflow calculations must align with cooling tower water testing and a reliable cooling tower water treatment system.

The total heat to be rejected is the foundation of airflow calculation:

Where:

The ambient wet bulb temperature sets the theoretical cooling limit. Lower wet bulb temperatures allow:

Less required air flow

Lower fan energy consumption

Wet bulb temperature is a critical design input for every water cooling tower.

Air density and specific heat vary with temperature and altitude. Typical design values:

Air density: 1.15–1.25 kg/m³

Specific heat of air: ~1.005 kJ/kg·°C

The most commonly used approach is based on heat transfer to air:

Cooling tower fans are rated in volumetric flow (m³/s):

This value is used for fan selection and tower sizing.

Engineers often use the L/G ratio:

Typical L/G ratios depend on:

Tower fill type

Design approach temperature

Whether the system is open or closed loop cooling tower

Manufacturers such as Mach Cooling provide optimized L/G ranges for each tower model.

| Parameter | Value |

|---|---|

| Water flow rate | 900 m³/h |

| Water inlet temperature | 40 °C |

| Water outlet temperature | 30 °C |

| Heat load | 10,500 kW |

| Air temperature rise | 8 °C |

| Air density | 1.2 kg/m³ |

This airflow value guides fan selection and tower geometry design.

Higher air flow increases evaporation. Adequate water supply capacity is required to maintain stable operation without interruptions.

Changes in airflow influence concentration cycles. Regular testing of:

Conductivity

pH

Hardness

ensures consistent heat transfer and protects internal components.

An effective treatment program reduces fouling and scaling, allowing the designed air flow rate to deliver full cooling performance without unnecessary fan power increases.

By accurately calculating air flow rate:

Fan energy is minimized

Evaporation losses are controlled

Overall cooling tower water use is optimized

This is especially important in regions with water scarcity.

| Cooling Tower Type | Typical Air Flow Range |

|---|---|

| Water cooled tower | Medium to high |

| Closed loop cooling tower | Medium |

| High-efficiency industrial tower | Optimized by L/G ratio |

Understanding how to calculate air flow rate in a cooling tower is fundamental for designing and operating an efficient water cooling tower system. By combining heat balance principles, air property data, and practical L/G ratios, engineers can accurately determine the required airflow for any water cooled tower or closed loop cooling tower.

Accurate airflow calculation supports:

Stable cooling performance

Reduced energy consumption

Controlled cooling tower water use

Reliable water chemistry management through proper cooling tower water testing and treatment

Professional manufacturers such as Mach Cooling (https://www.machcooling.com/) integrate these principles into their cooling tower designs, helping users achieve long-term reliability and efficiency.