We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-19 Origin: Site

Cooling towers are critical in industrial processes and HVAC systems for rejecting heat from circulating water. One of the most important operational considerations for cooling towers is water usage — specifically, how much water they consume and how to optimize that use. Understanding cooling tower water balance, makeup requirements, and ways to improve cooling tower water efficiency is essential for both performance and sustainability.

In this article, we’ll explore the factors affecting cooling tower water consumption, how makeup water works, and how advanced designs from manufacturers such as MACH Cooling (https://www.machcooling.com/) help reduce water usage and improve system efficiency.

Cooling towers operate by evaporative cooling — warm water from the system is sprayed into the tower and cooled as air passes through. The total water a cooling tower uses is the sum of losses through evaporation, drift, and blowdown.

The major components include:

Evaporation Loss: Water lost as heat is rejected

Drift Loss: Fine droplets carried out with exhaust air

Blowdown: Water discharged to control dissolved solids

Makeup Water: Fresh water required to replace losses

Understanding each of these components in the cooling tower water balance helps estimate total usage.

Evaporation is the largest contributor to cooling tower water use. It depends on:

Heat load

Wet bulb temperature

Water temperature difference

A chilled water cooling tower, for example, often has higher evaporative losses due to greater heat rejection requirements.

Drift: Tiny droplets escaping with airflow

Blowdown: Intentional water discharge to maintain water quality

Proper design and drift eliminator systems help reduce unnecessary drift, while controlled blowdown maintains system integrity.

Makeup water replaces all losses. The more efficient the system, the less fresh water is required.

Cooling tower makeup water is fresh water added to the system to replace:

Evaporation

Drift

Blowdown

Leakage

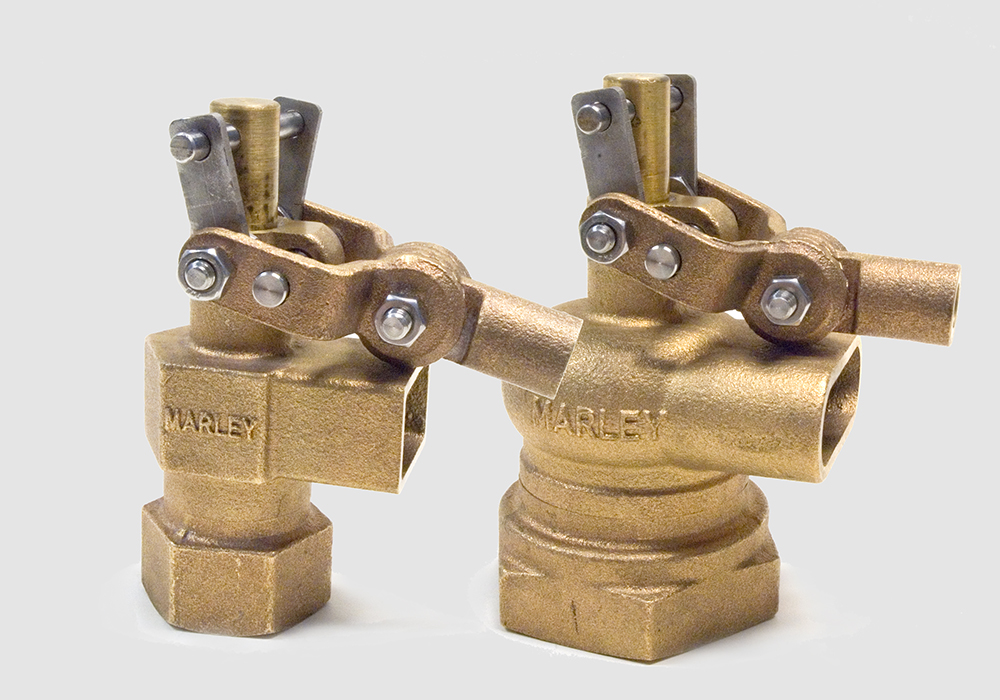

Makeup water enters through a cooling tower makeup water valve and is controlled by components such as the cooling tower makeup water float valve to maintain proper cooling tower water basin level.

The cooling tower makeup water float valve monitors the basin level and opens or closes to allow makeup water when needed, ensuring stable water levels and avoiding dry operation.

A typical water balance for a cooling tower is:

Makeup Water = Evaporation Loss + Drift Loss + Blowdown

| Water Component | Description |

|---|---|

| Evaporation Loss | Major loss due to heat rejection |

| Drift Loss | Water droplets carried out with air |

| Blowdown | Water discharged to control dissolved solids |

| Makeup Water | Fresh water added to replace total losses |

The cooling tower water flow rate refers to how quickly water circulates through the tower. Higher flow rates can mean better heat transfer — but they can also increase evaporation and makeup needs.

The cooling tower water distribution system and cooling tower water distribution nozzles are vital for effective coverage and heat transfer. Poor distribution leads to hot spots, increased evaporation, and higher water usage.

Ambient wet-bulb temperature

Humidity

Airflow

These environmental factors dictate how much water evaporates and how much makeup water is needed.

Systems with higher heat loads — such as large industrial processes or high-capacity HVAC — use more water due to greater cooling demands.

Cooling tower water loss includes:

Evaporative loss (necessary for heat rejection)

Drift loss (minimized with good design)

Blowdown (necessary for quality control)

Reducing unnecessary water loss improves efficiency and reduces operating cost.

Modern cooling towers focus on cooling tower water conservation — minimizing total water use through improved design and controls.

Accurate control of makeup water input using sensors and reliable float valves ensures water only enters when needed.

Effective water treatment allows for higher cycles of concentration, reducing blowdown-related water loss.

A well-designed cooling tower water distribution system ensures even distribution and minimizes unnecessary evaporation.

Real-time monitoring helps adjust water usage based on load and conditions.

MACH Cooling (https://www.machcooling.com/) specializes in high-performance cooling towers that prioritize water efficiency, durability, and ease of maintenance. Their systems include:

Efficient chilled water cooling tower designs

Precise cooling tower makeup water float valve controls

Optimized cooling tower water distribution nozzles

Integrated flow control to reduce cooling tower water consumption

| Feature | Benefit |

|---|---|

| Advanced water distribution design | Better heat transfer and water savings |

| Efficient makeup water controls | Less unnecessary water use |

| Durable construction | Long-term performance |

| Water balance optimization | Lower total consumption |

Understanding how much water a cooling tower uses is key to designing, operating, and maintaining efficient systems. A proper cooling tower water balance takes into account evaporation, drift, blowdown, and makeup requirements. By employing efficient distribution systems, intelligent makeup control, and conservation-focused strategies, facilities can reduce total water usage and operating costs.

Choosing a water-efficient partner like MACH Cooling ensures your systems use water responsibly while maintaining excellent cooling performance — essential for sustainable operations in modern industrial and commercial environments.