We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-18 Origin: Site

Cooling towers are essential components in many industrial and HVAC systems. They reject heat from water by bringing it into contact with air, enabling evaporative cooling that lowers the water temperature. At the heart of this process in many towers is the cooling tower fan — a key mechanical part of a water cooling tower system that enables efficient heat rejection and consistent cooling tower water supply and performance. This article explains how a cooling tower fan works, explores its types, and shows why it’s critical in maintaining the desired cooling tower water flow rate, proper cooling tower water management, and meeting cooling tower water requirements even in small or large installations like a small water cooling tower. It also highlights reliable solutions from the manufacturer MachCooling (https://www.machcooling.com/).

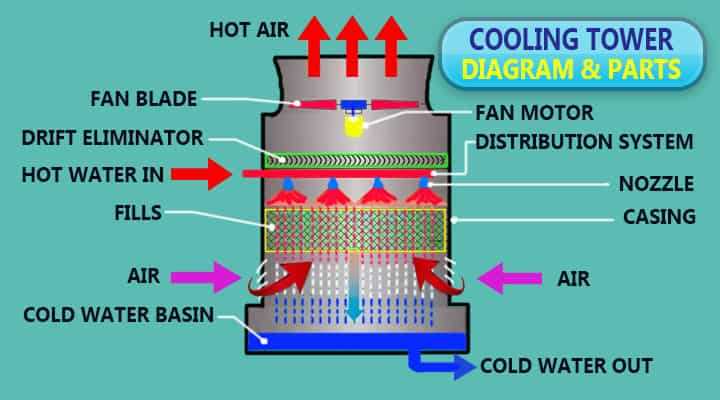

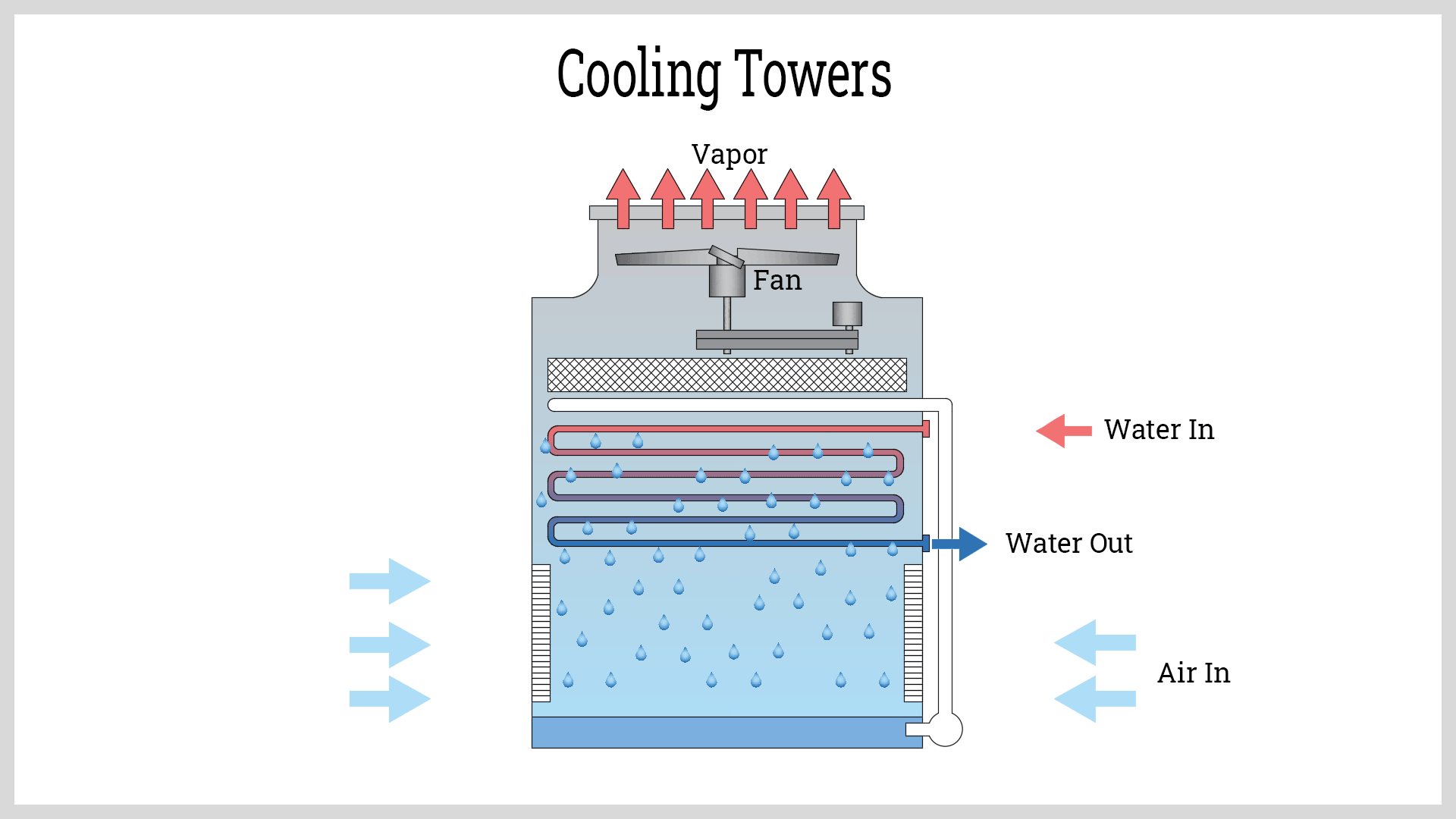

A cooling tower is a device designed to remove heat from recirculating water in industrial processes and HVAC systems. Warm water enters the tower, flows over specially designed surfaces called fill, and is cooled by air that flows through the tower. A portion of this water evaporates, removing heat from the bulk water. The cooled water then returns to the system for reuse.

For efficient cooling and heat rejection, you need:

Controlled airflow, often generated by a cooling tower fan

Good cooling tower water management

Correct cooling tower water usage

Balanced cooling tower water flow rate

Consistent cooling tower water supply

The fan ensures air flows through the fill media, directly affecting evaporation and cooling efficiency. Without adequate airflow, the water won’t cool effectively — even if all other components are optimal.

The cooling tower fan plays a central role by moving air across the tower:

Air Movement: The fan draws ambient air into the tower and through the wet fill media where warm water contacts air.

Enhanced Evaporation: The moving air increases the rate at which a portion of the water evaporates, which removes heat from the bulk water.

Uniform Cooling: It supports consistent heat rejection even when outdoor conditions (wind, humidity, temperature) vary.

Water Temperature Control: By adjusting the fan speed, operators can control the tower’s output water temperature to match system demand.

The fan ensures that warm water — part of the water cooling tower system — is effectively cooled before it circulates back into industrial processes or HVAC condensers.

Located at the top of the tower.

Pull air upward through the fill.

Reduces hot, moist air recirculation, keeping airflow efficient.

Common in many industrial cooling towers.

Ideal when you need a stable airflow independent of wind direction.

Positioned at the bottom or side of the tower.

Push air into the tower.

Easier to access for maintenance but can lead to some air recirculation.

Useful in systems with resistance to airflow or specific structural needs.

Tall, hyperbolic towers rely on natural convection instead of mechanical fans.

Air flows upward due to temperature differences.

Used in power plants and some large applications where a natural airflow can be sustained.

Fans are not present in this design, but mechanical draft cooling towers (with fans) provide more controlled airflow.

The fan is driven by an electric motor, either directly or via a gearbox or belt. In larger water cooling tower systems, the motor can be powerful enough to turn very large fan blades, often made of fiberglass or aluminum. These blades are designed to move large volumes of air efficiently.

In an induced draft system, air is pulled up through the fill and out the top.

In a forced draft design, air is pushed in at the bottom.

In both cases, the objective is to move cool air over the warm water dispersed across the fill media.

As air moves past the water droplets on the fill, some water evaporates. Evaporation is a highly effective cooling mechanism because it removes heat at a molecular level. The fan increases the contact between air and water, making this process much more efficient than natural convection alone.

Once cooled, the water is collected at the basin and pumped back through the system — whether to a chiller, condenser, or industrial process. The cooling tower water flow rate determines how much water needs to be cooled per unit time. Efficient fan performance supports the correct balance between air and water flow.

Many modern towers use variable speed drives on fans so that the airflow adjusts to real-time cooling needs. At lower load demands, the fan runs slower to save energy; at high load demands, it speeds up to provide maximum airflow.

Airflow affects cooling tower water usage because the more efficient the airflow, the more evaporative cooling you achieve with less water. Effective cooling tower water management — including the right fan control — reduces total water losses and supports optimized cooling tower water supply and reuse.

| Fan Speed Condition | Airflow Effect | Water Temperature Impact |

|---|---|---|

| Low speed | Lower airflow | Higher leaving water temp |

| Moderate speed | Balanced airflow | Target cooling |

| High speed | High airflow | Best cooling under hot/humid conditions |

This simplified table shows why fans are important — the right fan operation helps meet cooling tower water requirements under different environmental conditions.

In a small water cooling tower, the fan’s role is equally important:

Ensures effective evaporation even with limited water volumes

Maintains stable water flow and temperature for compact systems

Supports controlled cooling tower water flow rate

Minimizes excessive water consumption

MachCooling’s smaller fan-equipped towers deliver efficient all-weather performance for compact industrial or commercial applications. Learn more at https://www.machcooling.com/ for tailored small cooling towers.

MachCooling (https://www.machcooling.com/) is a manufacturer offering custom water cooling tower systems with advanced fan designs to meet different industrial needs:

High-efficiency cooling tower fans designed for optimal airflow

Solutions balancing cooling tower water flow rate and energy usage

Product lines suitable for both large industrial and small water cooling tower projects

Engineering support for cooling tower water management and meeting cooling tower water requirements

Explore their cooling tower solutions at https://www.machcooling.com/ for equipment designed to deliver dependable cooling performance tailored to your water and airflow needs.

The cooling tower fan is a key factor in an efficient water cooling tower system. By creating and controlling airflow through the tower, fans ensure effective heat removal, stable cooling tower water supply, and consistent system performance even as water load and ambient conditions vary. Whether in large industrial systems or a small water cooling tower, understanding how cooling tower fans work helps operators optimize performance, cut costs, and achieve effective cooling tower water management.