We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-07 Origin: Site

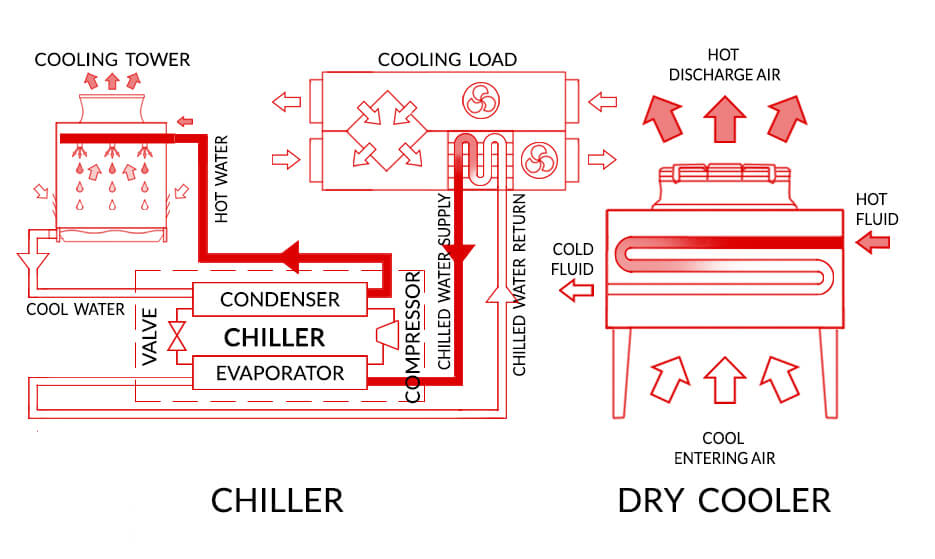

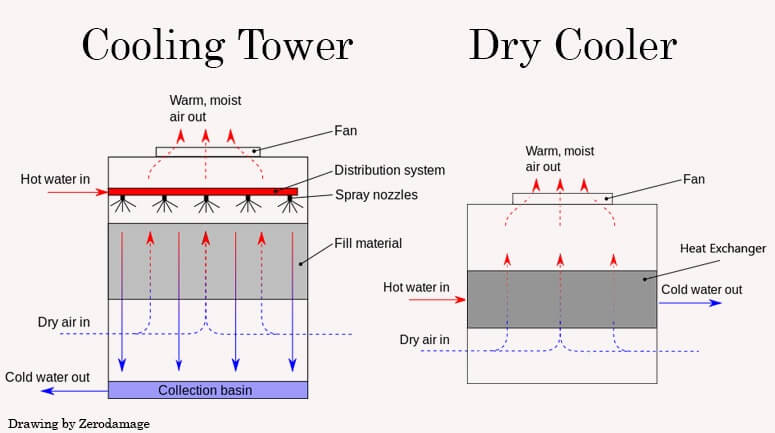

Dry cooling towers are increasingly popular in industries where water conservation and environmental compliance are critical. Unlike traditional wet towers, dry cooling towers rely on air to dissipate heat instead of evaporating water. Think of them as giant industrial radiators—they cool fluids without losing a single drop of water.

The shift toward dry cooling towers is not just a trend—it’s often a necessity for industries in water-scarce regions or environmentally sensitive areas.

One major advantage is the drastic reduction in water consumption. Since dry towers don’t rely on evaporation, they save thousands of gallons of water daily compared to wet towers.

In desert or semi-arid regions, where water is precious, dry cooling towers are often the only viable option. They allow large-scale cooling without straining local water resources.

At their core, dry cooling towers function similarly to car radiators.

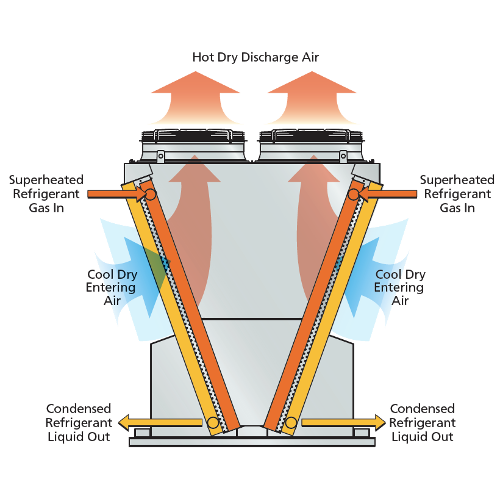

Hot process fluid—usually water or thermal oil—flows through a network of finned tubes. Large fans blow ambient air across these tubes, carrying heat away to the atmosphere. No evaporation occurs; all cooling is achieved via convection.

Unlike wet towers, dry systems do not create vapor plumes. This reduces visible emissions, water treatment requirements, and risk of bacterial contamination. However, they typically require larger surface areas to achieve the same cooling effect.

Also known as air-cooled condensers, these towers are straightforward and effective.

Finned tubes arranged for maximum airflow

High-efficiency fans for air movement

Simple, low-maintenance design

Small to medium industrial processes

HVAC systems in commercial buildings

Remote power generation units

These towers separate the process fluid from the air path, maintaining a closed-loop design.

Prevents fluid contamination

Heat is transferred via a secondary water or glycol loop

Suitable for sensitive fluids and high-temperature processes

Power plants using steam condensers

Petrochemical processes

Industries with strict fluid quality requirements

Hybrid towers combine dry and wet cooling principles for enhanced efficiency.

Uses air for primary cooling and minimal water spray for supplemental cooling

Reduces water use while maintaining high thermal efficiency

Adaptive operation depending on ambient conditions

Large-scale power plants in variable climates

Industries with seasonal cooling peaks

Locations with intermittent water availability

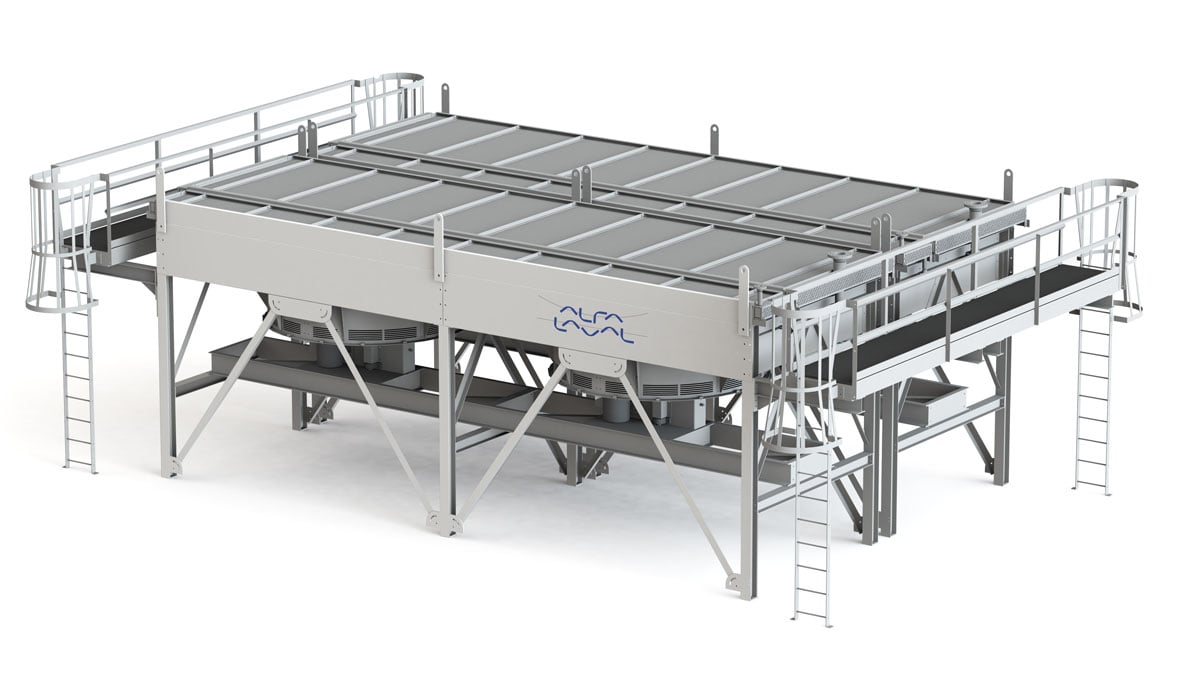

Designing an effective dry cooling tower involves balancing airflow, heat load, and durability.

Accurately estimating heat load is critical. Oversized towers waste space and energy, while undersized towers fail to meet cooling requirements.

Fans must match heat rejection needs and ambient conditions. Variable-speed drives allow energy-efficient operation under fluctuating loads.

Since the tower is exposed to outdoor conditions, materials must resist corrosion, UV degradation, and thermal cycling. Aluminum, stainless steel, and coated carbon steel are common choices.

Minimal water consumption

Lower risk of bacterial contamination

Reduced visible vapor plumes

Simplified water treatment

Suitable for remote locations

Larger footprint compared to wet towers

Higher initial capital cost

Reduced efficiency in extremely high ambient temperatures

Noise from large fans

Dry towers are widely used in coal, gas, and nuclear power plants, especially where water scarcity is a concern. They efficiently condense steam from turbines while conserving water.

Industries such as chemical, petrochemical, and metal processing rely on dry cooling for process heat removal, maintaining consistent operating temperatures without contaminating fluids.

Commercial and large-scale air conditioning systems also employ dry towers, particularly in areas with strict water-use regulations.

Regular inspection of fins and fans to prevent blockages

Periodic cleaning to remove dust, dirt, and debris

Monitor airflow and fan performance for efficiency

Inspect structural components for corrosion and wear

Mach Cooling specializes in designing and manufacturing dry cooling towers tailored for industrial and HVAC applications. Their solutions feature:

Optimized airflow and fin design for maximum efficiency

Durable materials for harsh environments

Hybrid options to balance water savings and cooling performance

Expert support from system design to maintenance

Learn more at https://www.machcooling.com/ to see how they deliver reliable, water-efficient cooling solutions.

Dry cooling towers are a water-saving, environmentally friendly solution for industries and HVAC systems. Understanding types, features, and applications helps engineers and contractors select the right system for their project.

By leveraging expertise from Mach Cooling, professionals can ensure reliable operation, lower water consumption, and long-term efficiency across various applications—from power generation to commercial HVAC.

Cooling Tower Vibration Switch Explained: How It Works And Why It Matters

Cooling Tower System Layout: From Water Inlet To Heat Rejection

Online Cooling Tower Resources for Engineers And Contractors

The Role of Cooling Tower Filtration in Water Quality Management

Understanding The Role of A Cooling Tower Basin in HVAC Systems

Advantages of Cross Flow Cooling Towers in Industrial Applications