We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-06 Origin: Site

Cooling towers are designed to run continuously, often in harsh industrial environments. While they may look rugged and self-sufficient, their performance depends heavily on daily operation and maintenance. Skipping daily checks is like ignoring the warning lights on your car dashboard—it might run today, but failure is quietly approaching.

This article provides a clear, practical, and publish-ready daily cooling tower operation and maintenance checklist, helping operators improve reliability, save water and energy, and extend equipment life.

Cooling tower problems rarely happen suddenly. Instead, they develop slowly—through minor imbalances in water chemistry, small mechanical issues, or unnoticed changes in operating conditions. Daily inspections catch these issues early, when they are easy and inexpensive to fix.

Consistent daily checks help you:

Prevent unplanned shutdowns

Maintain stable cooling performance

Reduce water and energy consumption

Improve safety and compliance

In short, daily maintenance protects both your equipment and your budget.

Cooling tower operation focuses on performance—temperatures, flow rates, and overall system behavior. Maintenance focuses on condition—mechanical health, cleanliness, and component integrity. Daily tasks sit right in the middle, combining observation with prevention.

Daily inspections don’t require senior engineers. Trained operators or facility technicians are ideal, as long as they understand what normal operation looks and sounds like. Consistency matters more than complexity.

Before starting the cooling tower, perform a quick walk-around:

Check casing panels, louvers, and access doors

Confirm ladders, platforms, and guardrails are secure

Look for visible leaks, cracks, or loose fasteners

If something appears damaged or out of place, it deserves attention before startup.

Inspect the basin for:

Proper water level

Debris, sludge, or biological growth

Smooth operation of the makeup water valve

Low basin levels can cause pump cavitation, while dirty basins reduce water quality and system efficiency.

Once the tower is running, observe the fan and motor:

Smooth startup without hesitation

Stable rotation and speed

No excessive heat from the motor housing

A motor that runs unusually hot is often signaling overload or airflow problems.

Unusual sounds—grinding, rattling, or humming—are early warnings. Vibration that can be felt through the structure usually points to imbalance, misalignment, or bearing wear.

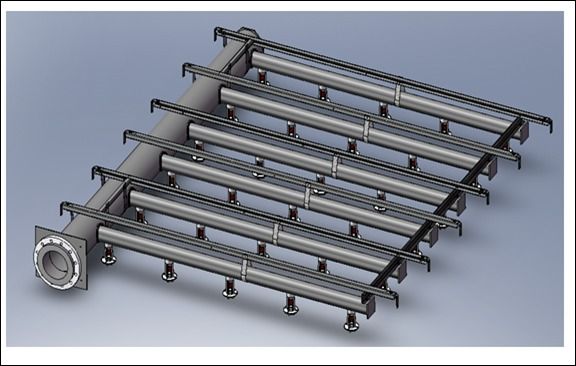

Check the water distribution system:

Spray nozzles should deliver even coverage

No dry spots should appear on the fill

Water flow should look uniform across the tower

Poor distribution reduces heat transfer efficiency and accelerates scaling.

Daily conductivity readings confirm whether blowdown control is functioning properly. Rising conductivity without adjustment increases the risk of scale and corrosion.

Maintaining stable cycles of concentration is one of the most effective ways to control water usage and protect equipment.

Visually inspect basin water:

Clear or slightly tinted water is normal

Cloudy, foamy, or foul-smelling water is not

Ensure chemical dosing pumps are operating and chemical storage levels are adequate.

Excessive water loss wastes water and chemicals. Daily checks should confirm:

Drift eliminators are intact and properly positioned

No abnormal splash-out around the tower

Makeup water usage remains consistent

Unexpected increases in makeup water demand often signal leaks or excessive drift.

Look and listen for:

Oil leaks around gearboxes

Unusual operating temperatures

Abnormal smells or noise

Lubrication issues almost always worsen if ignored.

Inspect belts and couplings for:

Proper tension

Visible wear or cracking

Signs of misalignment

Catching belt or coupling problems early prevents secondary damage.

Check the control panel for:

Alarm indicators or fault messages

Stable sensor readings

Proper controller response

A faulty sensor can lead to incorrect control decisions and serious system imbalance.

Ensure safety interlocks and alarms are enabled and functional. These systems exist to protect both personnel and equipment.

Daily operation plays a key role in reducing biological risk. Proper water circulation, correct chemical dosing, and avoidance of stagnant zones all help control Legionella and other microorganisms.

Consistent daily attention supports health, safety, and regulatory compliance.

A daily log transforms routine checks into actionable insight. Record:

Operating temperatures

Conductivity and makeup water usage

Observed abnormalities or corrective actions

Over time, these records reveal trends that help predict and prevent failures.

High vibration: Reduce load and inspect alignment or bearings

Rising conductivity: Check blowdown system and sensors

Uneven spray pattern: Inspect and clean nozzles

Quick action prevents small issues from becoming major failures.

Mach Cooling (https://www.machcooling.com/) designs industrial cooling towers with daily operation and maintenance in mind. From durable materials and corrosion-resistant components to layouts that allow easy inspection and service, Mach Cooling helps operators simplify daily checks while maximizing long-term reliability.

Good maintenance starts with good design.

Daily cooling tower operation and maintenance isn’t about adding work—it’s about avoiding risk. A consistent daily checklist keeps water chemistry balanced, mechanical components healthy, and energy consumption under control.

Make daily checks a habit, and your cooling tower will reward you with stable performance, lower costs, and a longer service life—every single day.

Cooling Tower Vibration Switch Explained: How It Works And Why It Matters

Cooling Tower System Layout: From Water Inlet To Heat Rejection

Online Cooling Tower Resources for Engineers And Contractors

The Role of Cooling Tower Filtration in Water Quality Management

Understanding The Role of A Cooling Tower Basin in HVAC Systems

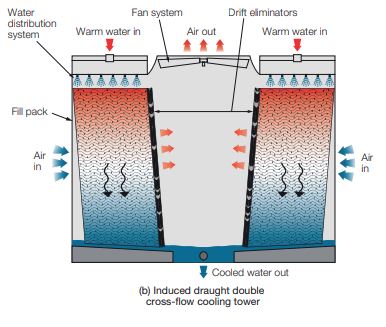

Advantages of Cross Flow Cooling Towers in Industrial Applications