We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-07 Origin: Site

If you’ve ever stared at a cooling tower and wondered, “How does water actually get cooled here?”—you’re not alone. The system layout of a cooling tower determines how efficiently water circulates, exchanges heat, and returns to the system. From the water inlet to heat rejection, every component plays a vital role. Think of it as a well-choreographed dance where water and air must interact just right to achieve maximum cooling.

A poorly designed layout can cause inefficiencies, frequent maintenance, and even early system failure. Conversely, an optimized layout improves performance, reduces energy costs, and prolongs equipment life.

When water flows evenly through the fill, fans operate efficiently, and the basin collects return water effectively, the system consumes less energy. Proper layout also reduces scaling, corrosion, and mechanical stress, extending the life of the cooling tower.

Mistakes include uneven water distribution, blocked airflow paths, undersized basins, or insufficient drift elimination. These errors can reduce cooling performance and increase maintenance requirements.

To understand system flow, it’s essential to know the key components of a cooling tower.

The water inlet is where hot water enters the tower from chillers or industrial processes. Proper placement and distribution prevent stagnation and ensure uniform flow over the fill media.

The basin collects cooled water at the bottom of the tower and acts as the starting point for recirculation. It must allow for sediment removal and easy maintenance access.

Fill media increases surface area for water to contact air, allowing heat to be removed efficiently. Correct spacing, height, and material selection are critical for optimal thermal performance.

Spray nozzles evenly distribute water over the fill. Proper nozzle selection and placement directly impact cooling efficiency and water coverage.

Drift eliminators prevent water droplets from escaping with the airflow, conserving water and maintaining efficiency. They also guide airflow across the fill in a controlled manner.

Fans drive air through the tower. Whether forced-draft or induced-draft, proper fan selection and placement ensure effective heat removal and system efficiency.

After cooling, water exits the basin via pumps back into the system. Proper outlet design ensures consistent flow and avoids recirculation issues.

Understanding the water and airflow path helps troubleshoot problems and optimize performance.

Hot water enters the tower through the inlet system. Uniform distribution across the fill is crucial; uneven flow creates hot spots and reduces efficiency.

Water trickles over the fill media, increasing contact with the air. Evaporation carries away heat, cooling the remaining water effectively.

Fans pull or push air through the fill. The air absorbs heat from the water and exits the tower as vapor. Proper airflow alignment maximizes thermal efficiency.

Cooled water collects in the basin and is pumped back into chillers or industrial loops. Basin design ensures sediment removal and prevents stagnant water zones.

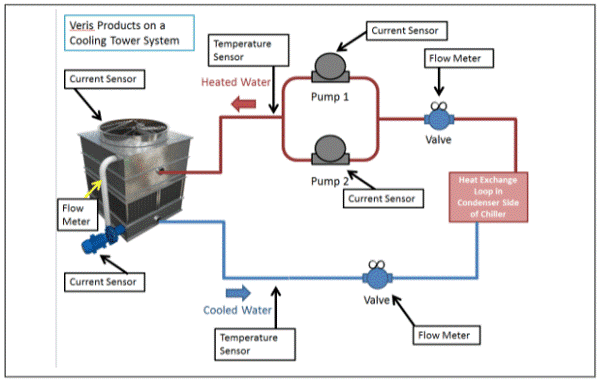

Cooling towers rarely operate in isolation. They integrate with chillers, process water loops, and heat exchangers. Understanding the layout ensures the tower meets design loads and adapts efficiently to changing operating conditions.

Even the best layout can be undermined by poor water quality. Filtration, chemical treatment, and regular maintenance ensure that the system remains clean, corrosion-free, and efficient.

Uneven water distribution: Use uniform spray nozzles and balanced headers.

Air recirculation issues: Ensure adequate spacing and proper tower orientation.

Sediment accumulation: Design basins for easy cleaning and integrate filtration systems.

Maintain uniform water distribution across fill media.

Keep airflow paths clear and ensure drift elimination.

Design basins for efficient sediment removal.

Match fan capacity to system load and environmental conditions.

Include water treatment and monitoring from the start.

Mach Cooling specializes in designing towers with optimized layouts from water inlet to heat rejection. Their expertise includes:

Precision water distribution systems

Durable fill media and drift eliminators

Energy-efficient fan and airflow arrangements

Seamless integration with HVAC and industrial loops

By combining engineering experience with modern materials and digital tools, Mach Cooling ensures high efficiency, lower operational costs, and extended equipment life.

Learn more at https://www.machcooling.com/.

A cooling tower’s system layout is more than just piping and fans—it’s a carefully choreographed flow of water and air. From the water inlet, through fill media and airflow, to the basin return, each step must be designed for efficiency, reliability, and longevity.

With proper planning, water treatment, and guidance from experts like Mach Cooling, engineers and contractors can maximize cooling performance while minimizing operational headaches.

Cooling Tower Vibration Switch Explained: How It Works And Why It Matters

Cooling Tower System Layout: From Water Inlet To Heat Rejection

Online Cooling Tower Resources for Engineers And Contractors

The Role of Cooling Tower Filtration in Water Quality Management

Understanding The Role of A Cooling Tower Basin in HVAC Systems

Advantages of Cross Flow Cooling Towers in Industrial Applications