We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-07 Origin: Site

When people think about cooling towers, they usually picture the tall structure, the fan on top, or the plume of vapor rising into the air. But the real work happens inside the cooling tower. This interior space is where heat exchange, water circulation, and airflow all come together.

Unfortunately, it’s also where many common and costly problems quietly develop. Because these issues are hidden from view, they’re often ignored until performance drops or failures occur.

The cooling tower interior is like the engine under a car’s hood. You don’t see it every day, but if something goes wrong inside, the whole system feels it.

Sediment buildup, corrosion, biological growth, and clogged components don’t usually cause immediate shutdowns. Instead, they slowly reduce efficiency, increase energy use, and shorten equipment life. By the time problems become visible, damage has often already been done.

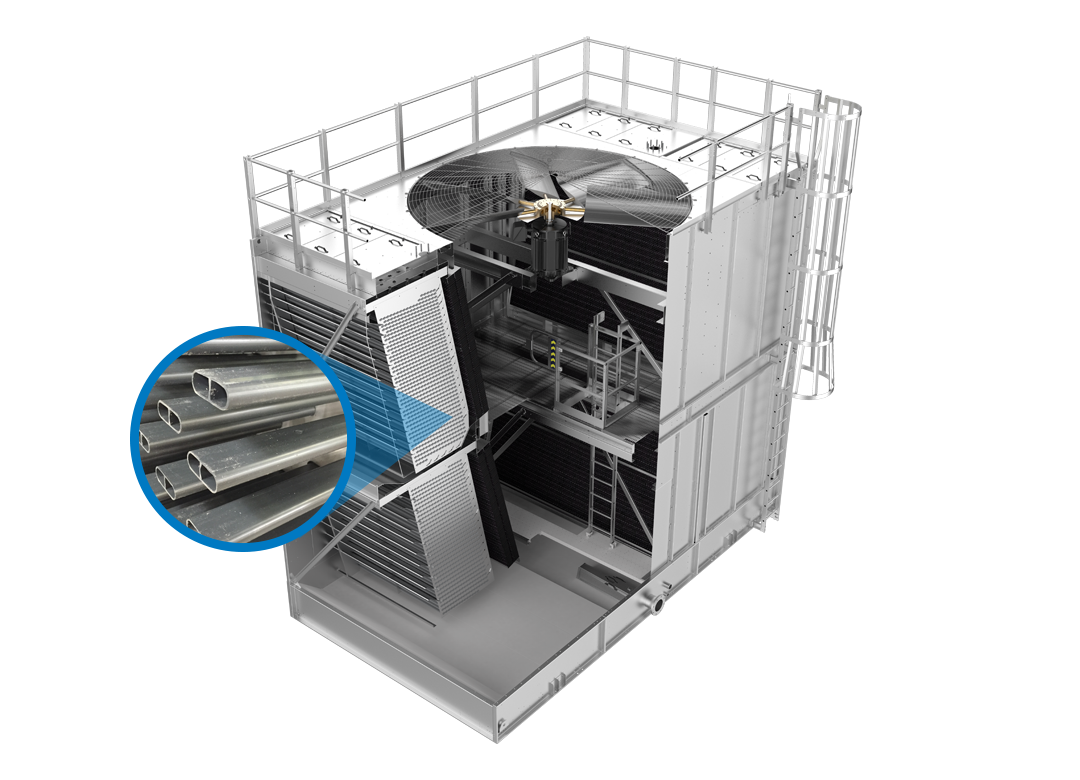

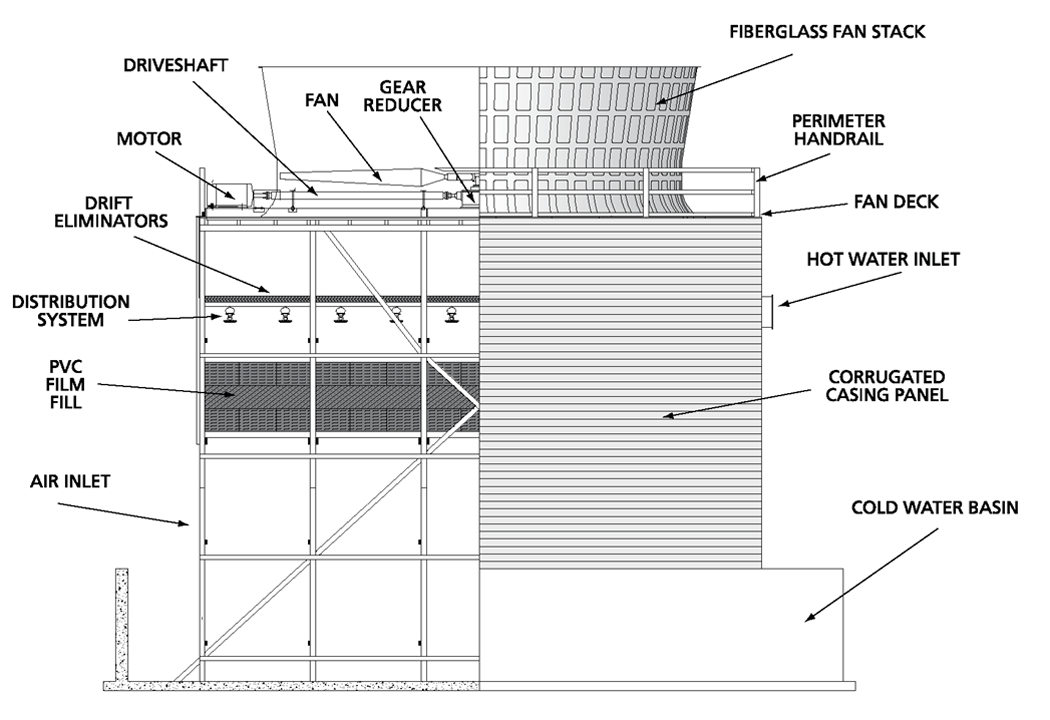

To understand interior problems, it helps to know what’s inside a cooling tower.

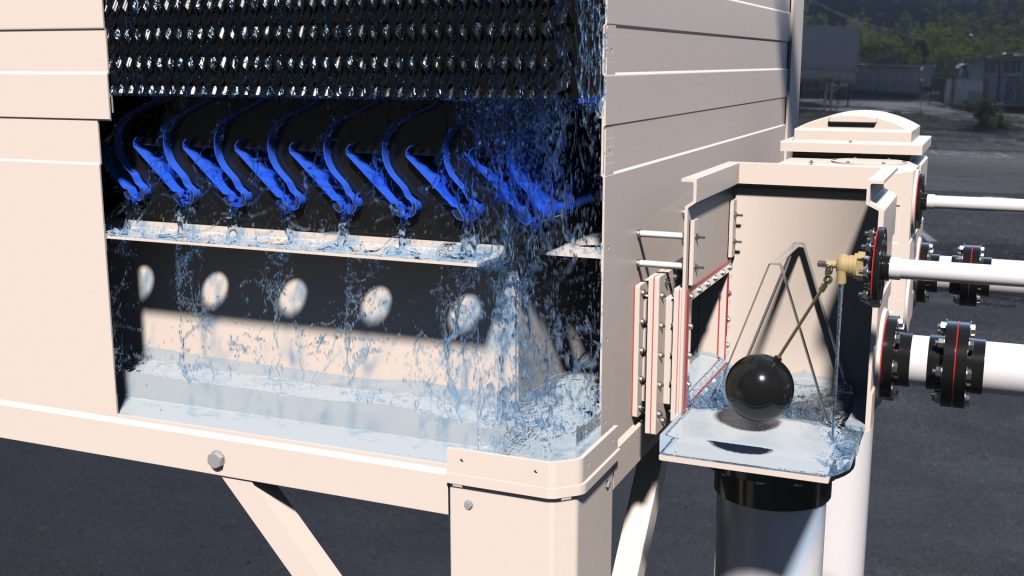

The basin collects cooled water and acts as the system’s lowest point. Because of gravity, dirt, debris, and solids naturally settle here.

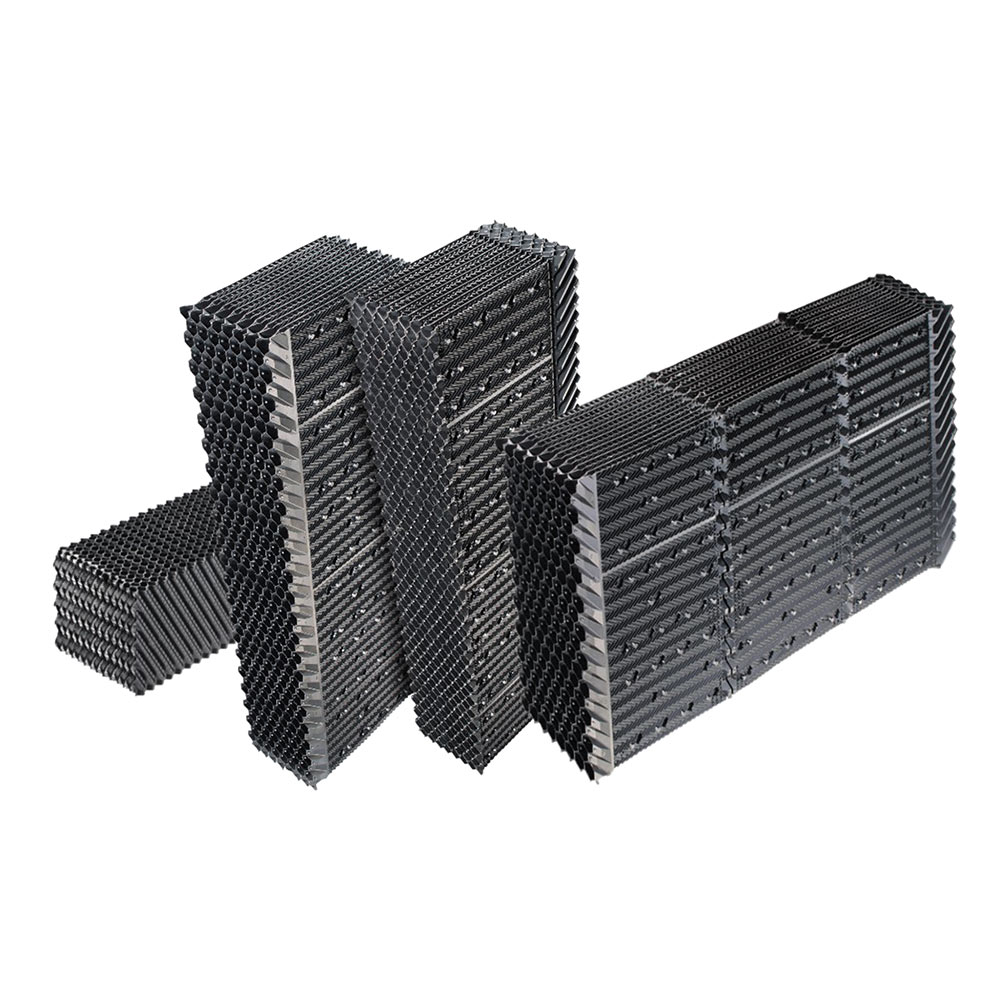

Fill media increases surface area for heat transfer, while drift eliminators prevent water droplets from escaping with airflow. Both are essential—and both are vulnerable to fouling.

Spray nozzles distribute hot water evenly over the fill. Any blockage or imbalance directly reduces cooling efficiency.

The internal structure supports all components. Corrosion or damage here threatens the tower’s mechanical integrity.

Sediment accumulation is one of the most common interior issues in cooling towers.

Airborne dust, sand, rust particles, and contaminants from makeup water enter the system continuously. Over time, these materials settle in the basin, forming sludge that restricts flow and creates an ideal environment for bacterial growth.

Scale is another frequent problem hidden inside cooling towers.

As water evaporates during cooling, dissolved minerals become more concentrated. Calcium and magnesium deposits harden on basin walls, piping, and fill media, acting like insulation and reducing heat transfer efficiency.

Corrosion is often called the silent killer—and for good reason.

Metal basins, supports, fasteners, and piping are especially susceptible. Poor water chemistry and oxygen-rich environments accelerate corrosion, leading to leaks, weakened structures, and unplanned shutdowns.

Warm water and nutrients make cooling tower interiors a perfect breeding ground for biological growth.

Once biofilm forms, it shields bacteria from chemical treatment. This not only reduces heat transfer but also increases health risks, including the potential growth of Legionella.

Spray nozzles may be small, but they play a big role.

When nozzles become clogged by sediment, scale, or biological matter, water distribution becomes uneven. Dry spots appear on the fill, and cooling performance drops almost immediately.

Fill media is designed to last, but harsh conditions take their toll.

Scaling, fouling, and chemical attack can cause fill to become brittle or collapse. Once airflow or water flow is restricted, the cooling tower struggles to meet design capacity.

Leaks inside the basin often start small and go unnoticed.

Cracks, corrosion, or poor sealing eventually lead to water loss, foundation damage, and higher operating costs if not repaired early.

Drift eliminators are designed to protect water and energy efficiency.

When blocked by dirt or biological growth, they restrict airflow and increase fan power consumption—much like breathing through a clogged filter.

Even water distribution is critical for effective cooling.

Blocked headers, damaged piping, or partially clogged nozzles lead to uneven loading inside the tower. Some areas are overloaded while others underperform, reducing overall efficiency.

Interior issues rarely exist in isolation. Together, they cause:

Reduced heat transfer efficiency

Higher energy consumption

Increased chemical usage

More frequent maintenance and downtime

Small internal problems can quickly snowball into major operational challenges.

Preventive maintenance is the most effective way to control interior problems.

Regular inspections, basin cleaning, nozzle checks, and water quality monitoring help detect issues early—before they become expensive repairs.

Many interior problems originate from poor design or material selection. Towers that are difficult to access, poorly drained, or made with low-quality materials are harder to maintain and more prone to failure.

As an experienced cooling tower manufacturer, Mach Cooling focuses on interior durability, smart layouts, and maintenance-friendly designs. From corrosion-resistant materials to optimized water distribution, Mach Cooling helps reduce common interior problems before they start.

Learn more at https://www.machcooling.com/.

Cooling tower interiors may be out of sight, but they should never be out of mind. Sediment buildup, scaling, corrosion, and biological growth are common problems—but with proper design, filtration, and maintenance, they are entirely manageable.

By understanding these interior challenges and working with experienced manufacturers like Mach Cooling, operators can ensure long-term efficiency, reliability, and safe operation of their cooling tower systems.

Cooling Tower Vibration Switch Explained: How It Works And Why It Matters

Cooling Tower System Layout: From Water Inlet To Heat Rejection

Online Cooling Tower Resources for Engineers And Contractors

The Role of Cooling Tower Filtration in Water Quality Management

Understanding The Role of A Cooling Tower Basin in HVAC Systems

Advantages of Cross Flow Cooling Towers in Industrial Applications