We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-11-19 Origin: Site

Cooling towers operate continuously under high temperature, high humidity, strong airflow, and unstable water quality conditions, making them prone to faults. Whether used in industrial processes or HVAC cooling systems, a cooling tower malfunction can quickly cause reduced cooling efficiency, production downtime, or severe equipment damage.

This guide summarizes the eight most common cooling tower failures, based on real engineering diagnostics. Each failure includes its causes, troubleshooting methods, and professional recommendations. Industry best practices from Mach Cooling (https://www.machcooling.com/) are also referenced for more reliable maintenance strategies.

Outlet water temperature consistently high

Overall cooling capacity decreases

Temperature alarms triggered in connected systems

PVC/PP fill clogged or aged

Uneven spray distribution or clogged nozzles

Insufficient water flow from the circulation pump

Inadequate air intake due to fan failure

Limescale buildup and poor water quality

Clean or replace fill packs

Clean nozzles to ensure proper spray coverage

Check pump flow and head pressure

Inspect fan motor, belt tension, and current load

Perform descaling and improve water treatment

|  |

Fan blade deformation or loose blade angle

Bearing lubrication failure

Gear reducer wear

Damaged louvers creating airflow turbulence

Air duct resonance

Correct and align fan blade pitch

Add lubrication to bearings

Inspect vibration and repair or replace the gear reducer

Replace broken louvers

Add sound insulation or optimize air duct design

Drift eliminators aged or deformed

Spray angle too wide, water droplets sucked into the fan

Fan speed too high

Install high-efficiency drift eliminators (reduce drift by 30%)

Adjust spray pressure and nozzle direction

Use a VFD (variable-frequency drive) to control airflow

Motor burnout

Control panel contactor failure

Belt slippage or breakage

Bearing seizure

Motor insulation degraded due to moisture

Check motor insulation, current load, and temperature

Inspect electrical control cabinet

Replace or tighten the belt

Add grease or replace bearings

Check for blade obstruction

Poor water quality

Nozzle scaling or debris accumulation

Sediment buildup inside spray pipeline

Insufficient spray pressure

Remove and clean nozzles

Flush spray headers and branch pipes with acid-cleaning

Check pump pressure

Replace aging nozzles (Mach Cooling offers high-efficiency spray components)

Lack of biocide treatment

Incorrect water chemistry

Sunlight exposure promoting algae growth

Unremoved sediment in the basin

Add biocides and scale inhibitors

Perform regular blowdown

Clean the cooling tower basin

Install automatic chemical dosing systems

Mechanical seal leakage

Impeller wear

Blockage at pump inlet filter

Motor overload

Replace mechanical seal

Replace worn impeller

Clean pump inlet strainer

Check motor load and electrical condition

FRP aging due to long-term exposure

Corrosion of steel components under acidic water

High humidity accelerating material fatigue

Apply anti-corrosion coating on steel components

Replace severely damaged FRP sections

Use enhanced corrosion-resistant FRP materials (Mach Cooling’s reinforced FRP options)

| Failure Type | Primary Cause | Recommended Solution |

|---|---|---|

| Poor cooling effect | Clogged fill / insufficient airflow | Clean fill; inspect fan and spray system |

| Excessive noise | Fan deformation / gearbox wear | Correct blades; add lubrication |

| Excessive drift | Drift eliminator aging | Replace drift eliminator; adjust airflow |

| Fan not running | Motor or belt failure | Inspect motor; tighten belt |

| Uneven spray | Clogged nozzles | Acid-clean spray lines |

| Water quality deterioration | Lack of biocide | Add chemicals; perform blowdown |

| Low pump flow | Impeller wear or blockage | Replace impeller; clean filters |

| Structural corrosion | FRP aging | Anti-corrosion repair; replace components |

Cooling tower maintenance and troubleshooting are multidisciplinary tasks involving mechanical engineering, hydrodynamics, airflow design, electrical control, and water treatment. Without systematic inspection, small issues can quickly escalate into major failures that affect cooling performance or even halt production.

The eight diagnostic methods in this guide allow engineers to quickly identify failure causes, reduce repair time, and significantly extend equipment lifespan.

For professional consultation, cooling tower upgrades, or new-system selection, you may refer to the trusted engineering manufacturer:

Mach Cooling – https://www.machcooling.com/

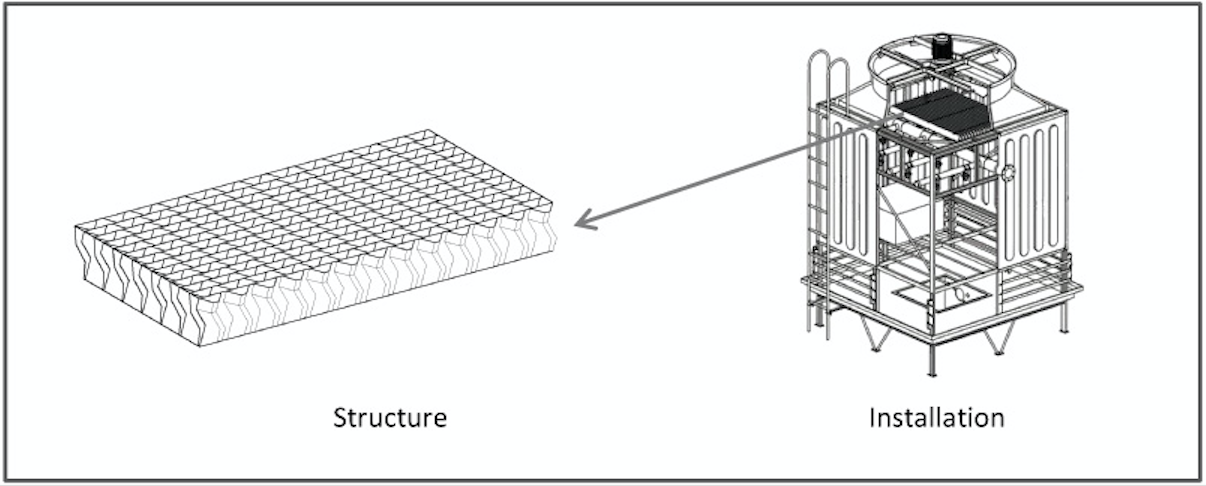

Mach Cooling provides reliable open-circuit and closed-circuit cooling towers, engineered for industrial environments and harsh operating conditions.

Cooling Tower Industry in Vietnam: Top Manufacturers Changing The Game in 2026

Leading Cooling Tower Brands in Myanmar You Can Trust in 2026: Global Rankings Revealed

Top 5 Cooling Tower Companies Dominating The Brunei Market in 2026

Best Cooling Tower Manufacturers in Laos: Ranking The Top 10 in 2026

How To Reduce Maintenance Costs with Cooling Tower Scale & Corrosion Inhibitors

Meet The Top 5 Cooling Tower Manufacturers in Thailand for 2026

Top 8 Cooling Tower Manufacturers in Indonesia: Leading Innovators in 2026

Top 10 Cooling Tower Manufacturers in Philippines in 2026: Industry Leaders & Market Insights