We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-13 Origin: Site

Choosing the right cooling tower is critical for ensuring efficient heat rejection, stable system operation, and long-term cost savings. With many options available — from open water cooling towers to closed loop and chilled water cooling tower systems — the question often arises: which cooling tower is best?

This article provides a comprehensive comparison of cooling tower types, selection criteria, and real-world applications, while introducing professional solutions from Mach Cooling, a trusted cooling tower manufacturer.

A cooling tower is a heat rejection device that removes waste heat from a system by cooling water through evaporation or indirect heat exchange. Cooling towers are widely used in HVAC systems, industrial processes, power plants, and refrigeration systems.

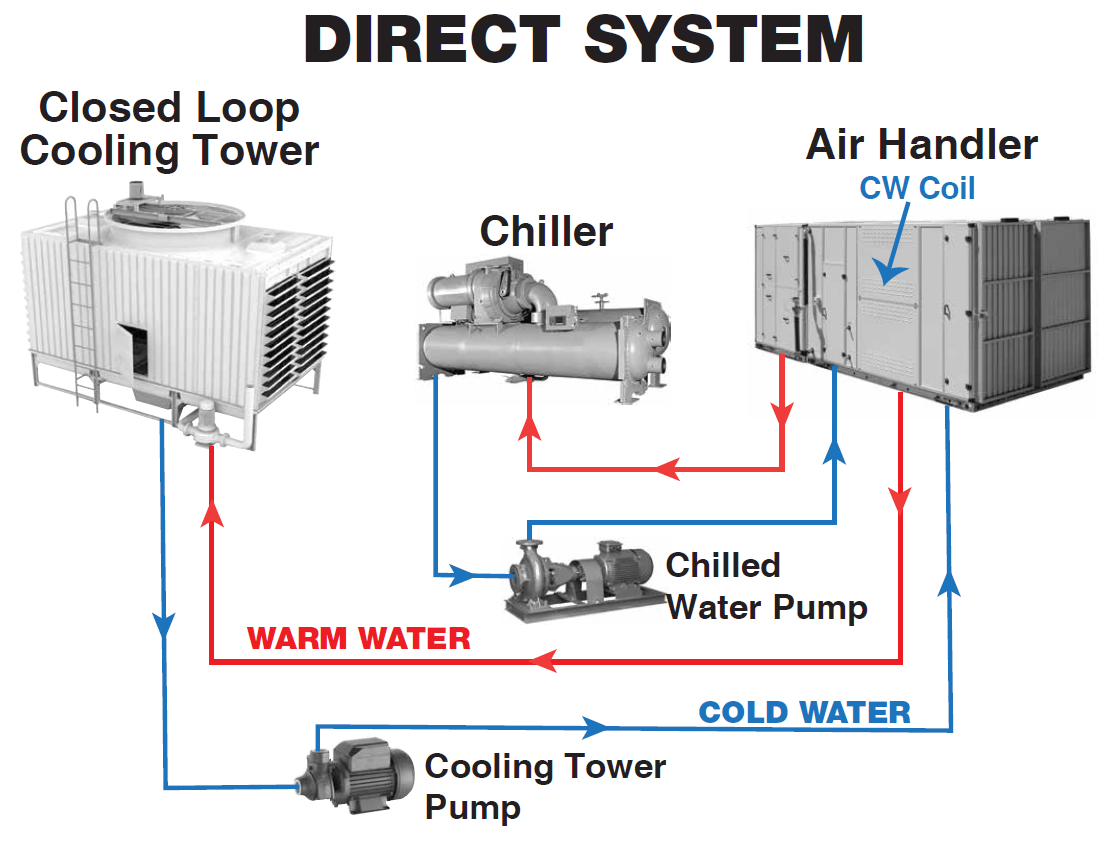

A complete water cooling tower system typically includes:

Cooling tower structure

Circulating pumps

Fans and motors

Heat exchangers or coils

Water treatment and blowdown systems

The best cooling tower depends on how these components are configured and matched to the application.

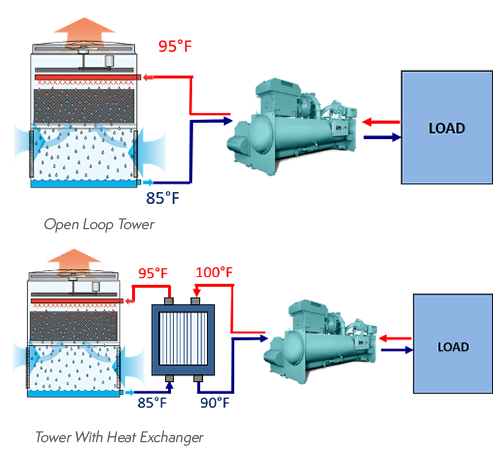

An open loop water cooling tower (also called a direct-contact or water cooled tower) allows cooling water to come into direct contact with ambient air. Heat is removed primarily through evaporation.

Simple structure

Lower initial investment

High cooling efficiency

Water is exposed to air contaminants

Requires frequent water treatment

Higher blowdown water volume

Typical applications:

HVAC condenser cooling, general industrial cooling, non-critical process systems.

A closed loop cooling tower uses a sealed heat exchanger coil. Process fluid circulates inside the coil, while spray water and air cool the coil externally. The process fluid never contacts air or contaminants.

Clean and stable process fluid

Reduced corrosion and scaling

Lower maintenance requirements

Longer equipment lifespan

Closed chilled water loops

Data centers

Chemical and pharmaceutical processes

Precision manufacturing

Mach Cooling offers high-efficiency closed loop cooling tower designs suitable for demanding industrial environments.

A chilled water cooling tower is an essential part of a cooling tower chilled water system, commonly used in large commercial buildings and industrial HVAC systems.

In this configuration:

The cooling tower removes heat from condenser water

Chillers produce chilled water for air conditioning or processes

Pumps and controls regulate flow and temperature

Stable chilled water temperature

Energy-efficient HVAC operation

Suitable for large-scale cooling demand

As water evaporates in a cooling tower, dissolved solids become concentrated. A blowdown water cooling tower system controls this concentration by discharging a portion of the circulating water and replacing it with fresh makeup water.

Prevents scaling and fouling

Controls corrosion and biological growth

Maintains heat transfer efficiency

Proper blowdown management is essential for both open and closed water cooling tower systems.

| Feature | Open Water Cooling Tower | Closed Loop Cooling Tower | Chilled Water Cooling Tower |

|---|---|---|---|

| Water–air contact | Direct | Indirect | Depends on design |

| Process water cleanliness | Medium | High | High |

| Maintenance level | Medium–High | Low | Medium |

| Initial cost | Lower | Higher | Medium |

| Water consumption | Higher | Lower | Medium |

| Best for | General cooling | Sensitive systems | HVAC & large buildings |

For sensitive fluids → Closed loop cooling tower

For general industrial cooling → Open water cooling tower

Poor or variable water quality → Systems with effective blowdown water cooling tower design

Clean or treated water → Closed loop systems reduce contamination risk

Variable-speed fans and optimized airflow improve efficiency

Proper integration with a cooling tower chilled water system reduces chiller load

Hot, humid climates favor evaporative cooling towers

Cold regions may require freeze-protection designs

Mach Cooling (https://www.machcooling.com/) specializes in designing and manufacturing high-quality cooling tower systems for industrial and commercial applications worldwide.

Open water cooling towers

Closed loop cooling towers

Counterflow and crossflow designs

Customized chilled water cooling tower solutions

Engineering-driven design

Reliable performance and long service life

Flexible configurations for different industries

Professional technical support

Mach Cooling systems are widely used in HVAC, power generation, chemical processing, and manufacturing industries.

Inspect fans, motors, and belts

Clean fill and spray nozzles

Monitor vibration and noise

Control scaling and corrosion

Maintain proper blowdown rate

Use appropriate water treatment chemicals

Freeze protection in winter

Drift control and plume management

Good maintenance ensures that both water cooled tower and closed loop cooling tower systems operate at peak efficiency.

There is no single “best” cooling tower for every application. The optimal choice depends on:

Cooling capacity requirements

Water quality

Energy efficiency goals

Maintenance expectations

For general industrial use, an open water cooling tower may be the most economical option. For sensitive systems and long-term reliability, a closed loop cooling tower is often the best choice. In HVAC applications, a properly designed chilled water cooling tower system delivers stable and efficient cooling.

With professional engineering, reliable manufacturing, and customized solutions, Mach Cooling provides cooling tower systems that help customers achieve the best balance of performance, efficiency, and cost.